1. 焊接設備、材料及焊接規范

①. 焊接設備:A120-400熔化極氣體保護焊機。

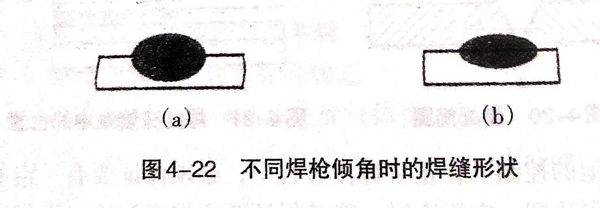

②. 母材:06Cr18Ni11Ti,厚度10mm, 600mm×300mm.裝配簡圖見圖4-20.

③. 實心焊絲:0Cr18Ni12V,?1.2mm.

④. 保護氣體:98%Ar+2%O2.

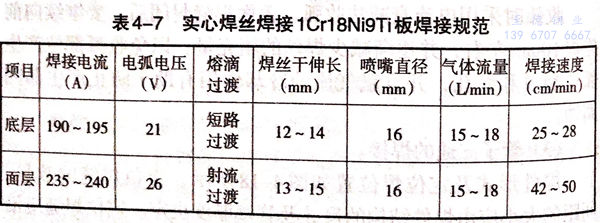

⑤. 焊接規范(fan):直流反接,焊接規范(fan)見表(biao)4-7。

2. 操作(zuo)要點

①. 焊槍的擺動(dong)

底(di)層焊(han)接采用左向焊(han)法月(yue)牙形擺(bai)動(dong),擺(bai)動(dong)幅度要均(jun)勻,在焊(han)縫兩(liang)側(ce)要作短(duan)時(shi)停留(liu),停留(liu)時(shi)電(dian)弧不得拉長。蓋(gai)面焊(han)同樣采用左向焊(han)法,月(yue)牙擺(bai)動(dong),與底(di)層焊(han)接不同的是,在焊(han)縫兩(liang)側(ce)停留(liu)的時(shi)間要比底(di)層焊(han)接時(shi)更長一些(xie)。

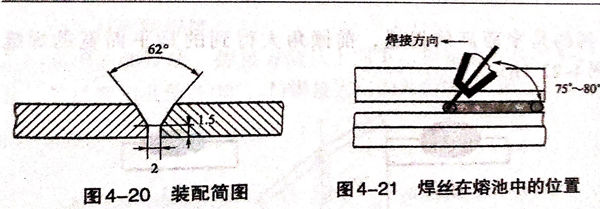

在底層焊(han)接(jie)時(shi),當第一個熔池(chi)(chi)(chi)形成后,焊(han)絲必(bi)須(xu)壓在熔池(chi)(chi)(chi)的(de)(de)(de)沿焊(han)縫縱向(xiang)的(de)(de)(de)1/2處橫向(xiang)擺動運行(圖4-21).在焊(han)接(jie)過(guo)程中(zhong),焊(han)絲始終在熔池(chi)(chi)(chi)內擺動,如果一旦焊(han)絲超過(guo)熔池(chi)(chi)(chi)往坡(po)口外擺動時(shi),會(hui)出現竄絲和頂絲現象,造成飛濺和根部燒穿、保(bao)護不好等缺(que)陷(xian)。當焊(han)接(jie)中(zhong)斷(duan)需(xu)要再次接(jie)頭時(shi),起(qi)弧(hu)點必(bi)須(xu)在熔池(chi)(chi)(chi)的(de)(de)(de)前端5~8mm處,此時(shi)在坡(po)口一側引弧(hu),當電弧(hu)穩定(ding)燃燒時(shi)快速將焊(han)絲拉到熔池(chi)(chi)(chi)內開始正常焊(han)接(jie)。

②. 熔池的控制

在正常焊(han)(han)(han)接過程中,必須保(bao)證(zheng)要有一(yi)定的(de)熔(rong)(rong)(rong)(rong)(rong)(rong)深(shen)。當熔(rong)(rong)(rong)(rong)(rong)(rong)深(shen)達到(dao)一(yi)定程度(du)(du)時,能夠保(bao)證(zheng)背面(mian)(mian)焊(han)(han)(han)縫(feng)焊(han)(han)(han)透(tou)。操(cao)作(zuo)時要及時觀察(cha)焊(han)(han)(han)接熔(rong)(rong)(rong)(rong)(rong)(rong)池前(qian)(qian)(qian)端的(de)熔(rong)(rong)(rong)(rong)(rong)(rong)孔(kong)(kong),熔(rong)(rong)(rong)(rong)(rong)(rong)孔(kong)(kong)尺(chi)寸(cun)始終保(bao)持在大(da)于間(jian)隙0.5~1mm.當發現(xian)熔(rong)(rong)(rong)(rong)(rong)(rong)孔(kong)(kong)尺(chi)寸(cun)逐漸增(zeng)大(da)時,說(shuo)明(ming)背面(mian)(mian)焊(han)(han)(han)縫(feng)在逐步(bu)增(zeng)高,再(zai)繼續下去將會導致焊(han)(han)(han)瘤或燒穿現(xian)象,此(ci)時應放慢速度(du)(du),將焊(han)(han)(han)絲往坡口兩(liang)邊運(yun)送或壓在熔(rong)(rong)(rong)(rong)(rong)(rong)池后面(mian)(mian)運(yun)行,直到(dao)熔(rong)(rong)(rong)(rong)(rong)(rong)孔(kong)(kong)尺(chi)寸(cun)恢復原狀,再(zai)繼續進行正常送絲焊(han)(han)(han)接。如果發現(xian)熔(rong)(rong)(rong)(rong)(rong)(rong)孔(kong)(kong)尺(chi)寸(cun)逐漸減小直至(zhi)沒(mei)有熔(rong)(rong)(rong)(rong)(rong)(rong)孔(kong)(kong),說(shuo)明(ming)背面(mian)(mian)焊(han)(han)(han)縫(feng)過低(di)甚至(zhi)出現(xian)未焊(han)(han)(han)透(tou),此(ci)時應加快前(qian)(qian)(qian)進速度(du)(du),焊(han)(han)(han)絲壓在熔(rong)(rong)(rong)(rong)(rong)(rong)池的(de)前(qian)(qian)(qian)半(ban)部或直線運(yun)絲,直到(dao)打開熔(rong)(rong)(rong)(rong)(rong)(rong)孔(kong)(kong)為正常尺(chi)寸(cun),再(zai)進行正常的(de)焊(han)(han)(han)接。

在(zai)蓋面焊(han)過(guo)程中,由于在(zai)大(da)電(dian)流下熔滴過(guo)渡屬于射流過(guo)渡,此(ci)時把握(wo)不當(dang)會出現熔寬增加(jia)、熔深減小、咬(yao)邊、焊(han)縫表面不規則等缺陷。

③. 導電(dian)嘴距離的(de)控(kong)制

操作時應注意導(dao)(dao)電嘴(zui)(zui)與(yu)焊縫表(biao)面的(de)(de)距離(li)。導(dao)(dao)電嘴(zui)(zui)距離(li)過低:第(di)一,會影(ying)焊工視線;第(di)二,使過渡金(jin)屬受(shou)保護氣(qi)體的(de)(de)壓縮(suo)后(hou)沖擊熔(rong)池(chi),使熔(rong)池(chi)產(chan)生(sheng)較(jiao)大的(de)(de)波動(dong)而造成(cheng)焊縫表(biao)面的(de)(de)不(bu)平(ping);第(di)三,氣(qi)體保護過近易(yi)造成(cheng)紊流產(chan)生(sheng)氣(qi)孔。導(dao)(dao)電嘴(zui)(zui)距離(li)過高會使氣(qi)體保護效果(guo)變差,也容易(yi)產(chan)生(sheng)氣(qi)孔、飛濺、咬(yao)邊等缺陷。

合理的(de)方(fang)法是(shi),導電嘴距離焊縫表(biao)面8~10mm,焊接時(shi)中間快,兩邊(bian)停留(liu),尤其在兩邊(bian)停留(liu)時(shi),應控制導電嘴的(de)高度,否則易出(chu)現咬邊(bian)缺陷。

④. 焊槍角(jiao)度的控制

焊縫表面的余高(gao)、熔寬與焊槍(qiang)角度有著很大(da)的關系,焊槍(qiang)前傾角越(yue)小或垂直(zhi)于工(gong)件(jian)(圖(tu)4-22(a)),得到(dao)的是窄而高(gao)的焊縫,前傾角大(da)得到(dao)的是平而寬的焊縫(圖(tu)4-22(b))。