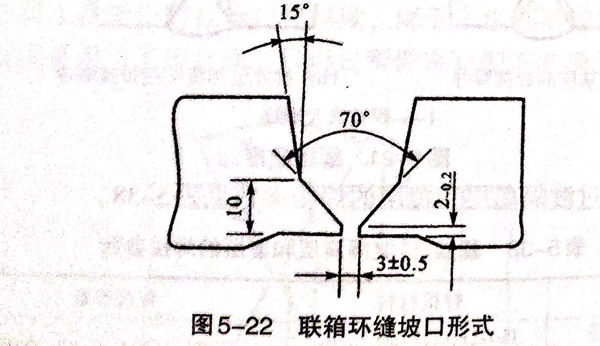

聯(lian)箱材質為12Cr1MoV,如(ru)圖5-22所示。采用(yong)(yong)焊條電(dian)弧(hu)焊打底(di)和埋弧(hu)自動焊蓋面,用(yong)(yong)定(ding)(ding)位(wei)塊將聯(lian)箱筒節固(gu)定(ding)(ding)在(zai)一(yi)起(qi),沿圓周(zhou)每隔200~300mm裝一(yi)塊定(ding)(ding)位(wei)塊,并均勻分布;定(ding)(ding)位(wei)塊焊接時,工件應預熱至250℃.

嚴格(ge)控制坡(po)口鈍(dun)邊厚度(du)和裝配間(jian)隙(xi)(xi)。鈍(dun)邊過大(da)、間(jian)隙(xi)(xi)過小,易產(chan)生未(wei)焊(han)(han)(han)透(tou);鈍(dun)邊過小、間(jian)隙(xi)(xi)過大(da),則易產(chan)生燒穿。聯箱放在(zai)滾輪架上,采用火焰或感應加熱法(fa),將焊(han)(han)(han)口預熱至300℃.打底焊(han)(han)(han)時(shi),從時(shi)針十(shi)點半(ban)位置開(kai)始(shi)進行下(xia)坡(po)焊(han)(han)(han),焊(han)(han)(han)接電(dian)(dian)流(liu)比立焊(han)(han)(han)略小一(yi)(yi)些(xie),ф3.2mm焊(han)(han)(han)條選用電(dian)(dian)流(liu)100~110A,ф4mm焊(han)(han)(han)條選用電(dian)(dian)流(liu)130~140A,隨時(shi)對熔池觀察,判(pan)斷熔透(tou)情況(kuang),并以合適的運條方法(fa)保證根部焊(han)(han)(han)透(tou)。第(di)2層起,可在(zai)時(shi)針十(shi)一(yi)(yi)點四(si)十(shi)五分位置開(kai)始(shi)進行下(xia)坡(po)焊(han)(han)(han),一(yi)(yi)直到10mm焊(han)(han)(han)縫為(wei)止,隨后再進行埋弧自動(dong)焊(han)(han)(han)。

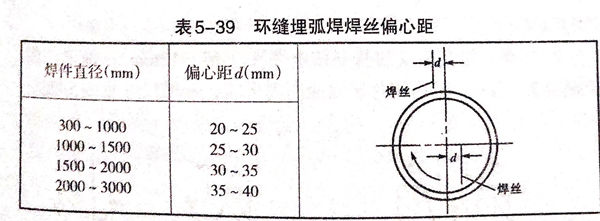

埋弧自動(dong)焊(han)的焊(han)絲位置見(jian)表5-39.焊(han)絲直徑?4mm,焊(han)接電(dian)(dian)流450~500A,電(dian)(dian)弧電(dian)(dian)壓(ya)28~30V,焊(han)接速(su)度28~30m/h.

焊后經外觀、表面磁粉(fen)和射線或(huo)超聲(sheng)波檢查合格,進行710~750℃的焊后回火。