目(mu)前卷(juan)軋(ya)中(zhong)厚板軋(ya)機的(de)主要有以下(xia)三種種生產工藝:

1. 單張鋼板(ban)往復軋(ya)制方式

這(zhe)種方式主要用(yong)于(yu)(yu)軋(ya)制(zhi)厚度大于(yu)(yu)20毫(hao)米的厚鋼(gang)(gang)板(ban),使用(yong)較長(chang)的板(ban)坯,當軋(ya)制(zhi)到(dao)目(mu)標(biao)鋼(gang)(gang)板(ban)厚度時,最(zui)終(zhong)長(chang)度大于(yu)(yu)50米(一般不(bu)超(chao)過100米),軋(ya)件直接從出口卷取爐下面送至轉鼓飛剪(jian),將之剪(jian)切成倍尺母板(ban)長(chang)度;通過加速冷卻后進入熱矯直機(ji)及冷床;最(zui)后經精(jing)整(zheng)線剪(jian)切出定尺成品鋼(gang)(gang)板(ban)。這(zhe)種方式適于(yu)(yu)常規的中厚板(ban)生(sheng)產工藝(yi)。

2. 卷軋(ya)鋼(gang)板方式(shi)

這種方式(shi)主要用(yong)于(yu)軋(ya)(ya)制(zhi)生產厚(hou)度(du)(du)不(bu)(bu)超過(guo)(guo)20毫(hao)米的(de)(de)中厚(hou)鋼(gang)板(ban)(ban)(ban)。使用(yong)較(jiao)長板(ban)(ban)(ban)坯,先在軋(ya)(ya)機(ji)(ji)(ji)上(shang)經(jing)(jing)反復可逆軋(ya)(ya)制(zhi),當(dang)軋(ya)(ya)件厚(hou)度(du)(du)不(bu)(bu)超過(guo)(guo)25毫(hao)米時,長軋(ya)(ya)件進(jin)入(ru)(ru)軋(ya)(ya)機(ji)(ji)(ji)入(ru)(ru)口或出口卷(juan)取爐進(jin)行(xing)保(bao)溫,經(jing)(jing)往復軋(ya)(ya)制(zhi),最終軋(ya)(ya)至(zhi)(zhi)成(cheng)(cheng)品厚(hou)度(du)(du);然(ran)后(hou)(hou)從出口卷(juan)取爐下(xia)面送往飛剪(jian)剪(jian)切成(cheng)(cheng)長度(du)(du)不(bu)(bu)超過(guo)(guo)50米的(de)(de)母板(ban)(ban)(ban),再經(jing)(jing)熱(re)矯直機(ji)(ji)(ji)矯直,冷床冷卻,在精整線剪(jian)切成(cheng)(cheng)定(ding)尺長度(du)(du)鋼(gang)板(ban)(ban)(ban)。這種生產工藝(yi)是(shi)(shi)卷(juan)軋(ya)(ya)中厚(hou)板(ban)(ban)(ban)軋(ya)(ya)機(ji)(ji)(ji)特(te)有(you)的(de)(de)生產工藝(yi)。卷(juan)軋(ya)(ya)板(ban)(ban)(ban)生產方式(shi)既(ji)不(bu)(bu)同(tong)于(yu)普通中板(ban)(ban)(ban)生產方式(shi),也(ye)不(bu)(bu)同(tong)于(yu)熱(re)連軋(ya)(ya)鋼(gang)卷(juan)生產方式(shi)。由于(yu)其采用(yong)的(de)(de)是(shi)(shi)當(dang)軋(ya)(ya)件軋(ya)(ya)至(zhi)(zhi)厚(hou)度(du)(du)不(bu)(bu)超過(guo)(guo)25毫(hao)米,長軋(ya)(ya)件進(jin)入(ru)(ru)機(ji)(ji)(ji)前(qian)或機(ji)(ji)(ji)后(hou)(hou)卷(juan)取爐進(jin)行(xing)保(bao)溫方式(shi),因(yin)此既(ji)減少了軋(ya)(ya)件的(de)(de)溫降,也(ye)可使軋(ya)(ya)件在卷(juan)取爐與軋(ya)(ya)機(ji)(ji)(ji)之間形成(cheng)(cheng)張力,進(jin)而(er)可減小軋(ya)(ya)件縱(zong)向(xiang)的(de)(de)變(bian)形抗(kang)力。由于(yu)卷(juan)軋(ya)(ya)鋼(gang)板(ban)(ban)(ban)具有(you)上(shang)述(shu)特(te)點(dian),因(yin)而(er)可使軋(ya)(ya)件軋(ya)(ya)得(de)更(geng)薄,并能得(de)到較(jiao)好的(de)(de)板(ban)(ban)(ban)形。

3. 鋼卷軋制方式

這種方式用于軋(ya)(ya)制(zhi)(zhi)商(shang)品鋼卷(juan)(juan)(juan)。采(cai)用出、入(ru)口卷(juan)(juan)(juan)取(qu)爐,將軋(ya)(ya)件往(wang)復軋(ya)(ya)至(zhi)厚(hou)2.5~20.0毫米的(de)帶鋼,經層流冷卻后進(jin)入(ru)地(di)下卷(juan)(juan)(juan)取(qu)機(ji)(ji)(ji)卷(juan)(juan)(juan)成鋼卷(juan)(juan)(juan)。綜合了(le)熱(re)連軋(ya)(ya)機(ji)(ji)(ji)和中(zhong)厚(hou)板(ban)軋(ya)(ya)機(ji)(ji)(ji)的(de)技(ji)術(shu)(shu)(shu)特點,形成了(le)現代(dai)卷(juan)(juan)(juan)軋(ya)(ya)中(zhong)厚(hou)板(ban)軋(ya)(ya)機(ji)(ji)(ji)的(de)技(ji)術(shu)(shu)(shu)特色。采(cai)用的(de)主要技(ji)術(shu)(shu)(shu)有:直接熱(re)裝(zhuang)技(ji)術(shu)(shu)(shu),最高(gao)可達到75%;爐卷(juan)(juan)(juan)軋(ya)(ya)制(zhi)(zhi)工(gong)藝技(ji)術(shu)(shu)(shu);控(kong)制(zhi)(zhi)軋(ya)(ya)制(zhi)(zhi)及(ji)熱(re)機(ji)(ji)(ji)軋(ya)(ya)制(zhi)(zhi)工(gong)藝技(ji)術(shu)(shu)(shu)(可滿(man)足生(sheng)產管線鋼、高(gao)強度(du)造船板(ban)、高(gao)強度(du)結(jie)構(gou)鋼板(ban)的(de)要求);高(gao)精度(du)、快(kuai)速(su)動(dong)態自動(dong)厚(hou)度(du)控(kong)制(zhi)(zhi)技(ji)術(shu)(shu)(shu)(AGC);板(ban)形控(kong)制(zhi)(zhi)(目(mu)前僅(jin)限(xian)于軋(ya)(ya)輥(gun)彎輥(gun))技(ji)術(shu)(shu)(shu);控(kong)制(zhi)(zhi)冷卻及(ji)層流冷卻+加速(su)冷卻技(ji)術(shu)(shu)(shu);全液壓地(di)下卷(juan)(juan)(juan)取(qu)機(ji)(ji)(ji)及(ji)自動(dong)踏步控(kong)制(zhi)(zhi)技(ji)術(shu)(shu)(shu)等。

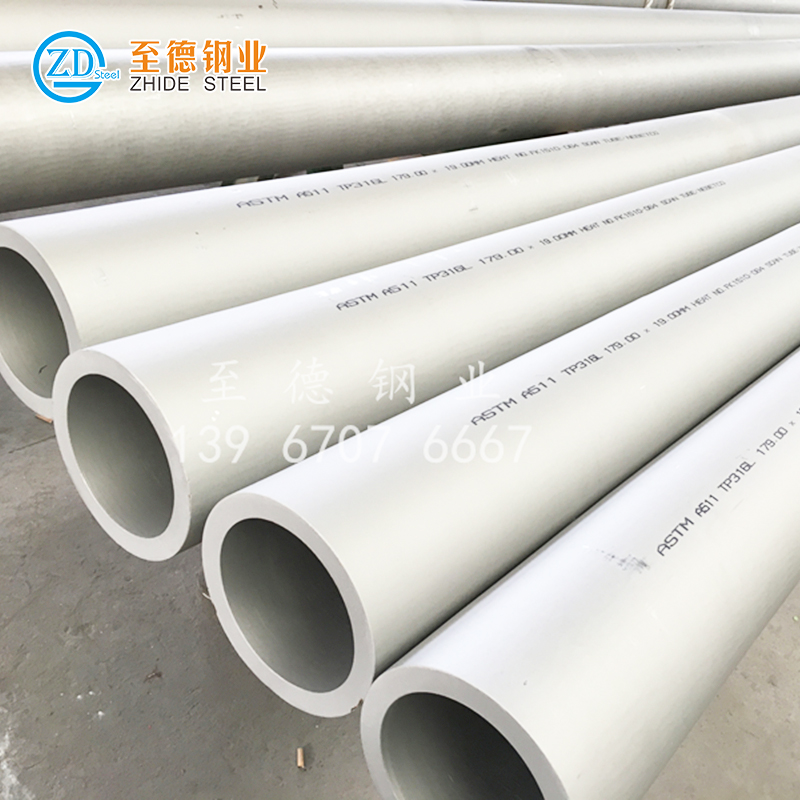

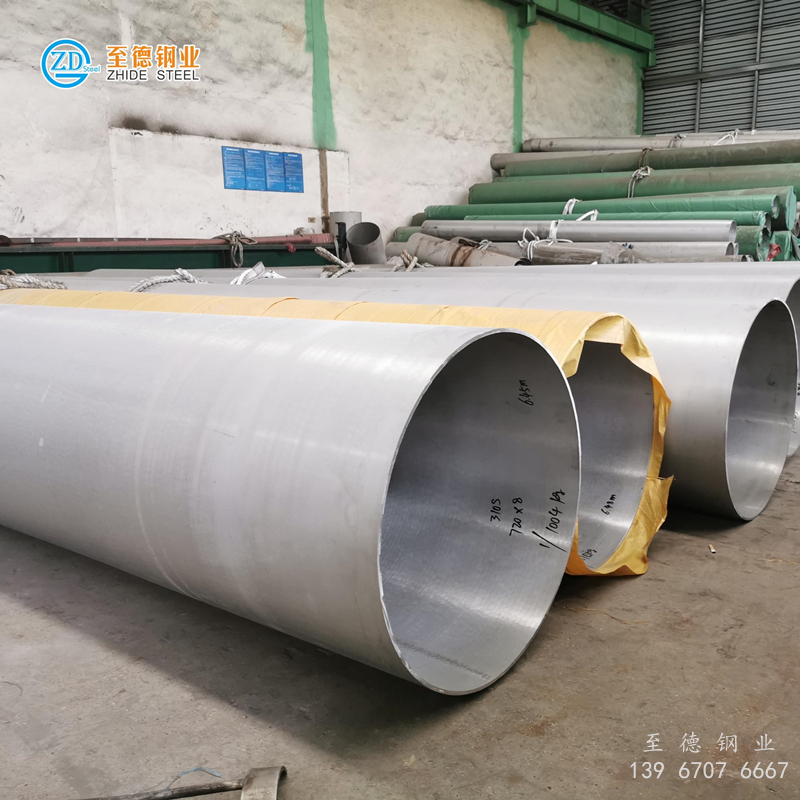

至德鋼業,我們根據您的實際需求,給出(chu)參考建議,為您提(ti)供高性價(jia)比的不銹鋼管道及配件。