1. 電(dian)刷鍍錫目的物

15Cr11MoVA不銹鋼(gang)套筒是汽輪機(ji)組上(shang)的(de)重(zhong)要零件。由于它在高(gao)(gao)溫、高(gao)(gao)壓(ya)下長期工作,因而(er)要求它的(de)內(nei)部(bu)表(biao)面(mian)(mian)和(he)(he)小孔具有高(gao)(gao)強度,高(gao)(gao)的(de)抗蝕性和(he)(he)耐磨(mo)性,而(er)外(wai)部(bu)表(biao)面(mian)(mian)則要求具有良好的(de)可加工性。為(wei)了滿足這(zhe)些要求,對(dui)套筒內(nei)表(biao)面(mian)(mian)和(he)(he)小孔要進行(xing)氮(dan)化處理(li),而(er)對(dui)其外(wai)部(bu)表(biao)面(mian)(mian)應(ying)采取鍍(du)錫防滲(shen)氮(dan)措施。

2. 電刷(shua)鍍錫工藝(yi)流程

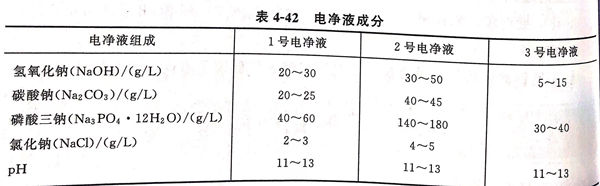

電(dian)(dian)(dian)凈(jing)(電(dian)(dian)(dian)凈(jing)溶液(ye)見(jian)表4-42中(zhong)的 1號(hao)電(dian)(dian)(dian)凈(jing)液(ye),工(gong)(gong)作電(dian)(dian)(dian)16V,時間(jian)為(wei)(wei)電(dian)(dian)(dian)凈(jing)至表面(mian)均(jun)勻潤濕不掛水珠為(wei)(wei)止(zhi))→水沖洗→活化(活化溶液(ye)成分(fen)硫(liu)酸(suan) 80g/L,硫(liu)酸(suan)銨110g/L,電(dian)(dian)(dian)壓(ya)(ya)為(wei)(wei)+12V,反(fan)接(jie),即工(gong)(gong)件接(jie)正(zheng)極(ji),鍍筆接(jie)負(fu)極(ji),表面(mian)活化至均(jun)勻淺灰色(se)后(hou),變電(dian)(dian)(dian)壓(ya)(ya)為(wei)(wei)-12V,正(zheng)接(jie),即工(gong)(gong)件接(jie)負(fu)極(ji),表面(mian)活化至均(jun)勻較深灰色(se)為(wei)(wei)止(zhi))→水沖洗→刷鍍錫[鍍錫溶液(ye)成分(fen)參(can)見(jian)4.9.12之(3),工(gong)(gong)作電(dian)(dian)(dian)壓(ya)(ya) 3~7V,溫度(du)室溫,陽極(ji)與工(gong)(gong)件之間(jian)的相對運動速率為(wei)(wei)15~16m/min,錫層(ceng)厚(hou)度(du)為(wei)(wei) 6~7μm]→水→中(zhong)和(he)(用電(dian)(dian)(dian)凈(jing)液(ye)無電(dian)(dian)(dian)擦技)→熱水授泡(溫度(du) 50℃熱水,時間(jian)5min)→干(gan)燥→氨化(鍍錫后(hou)3天內)。

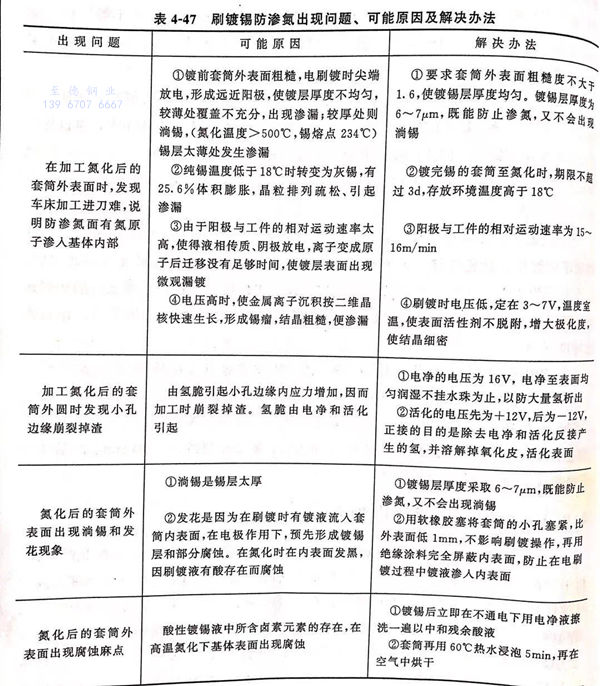

3. 刷鍍錫防(fang)滲(shen)氮(dan)出現問題,可能原因及解決辦法見表(biao) 4- 47 。