壓鑄通常是在壓力作用下,將熔融金屬射入閉合的鑄型及壓型中,金屬在模型內凝固成尺寸精確的鑄件。冷卻后開啟鑄型將鑄件脫出,隨后再閉合鑄型射入熔融金屬以鑄造下一個鑄件,這樣依次進行。鑄型的開啟、閉合以及熔融金屬的壓射,通常都是由壓鑄機來完成的。一般來說,壓鑄機的體積大、強度高,足以承受鑄型閉合后射入金屬時所施加的壓力。

目前(qian),壓鑄(zhu)已成為(wei)工(gong)(gong)業化、大批量(liang)生產(chan)輕(qing)金屬制(zhi)品的主(zhu)要成型(xing)方法(fa),特別(bie)是(shi)鋁、鋅及(ji)鎂(mei)等(deng)合金,并已發(fa)展到一定自動化的程度。壓鑄(zhu)提供從(cong)原材料到成品的一種低成本、大批量(liang)的生產(chan)方式。壓鑄(zhu)法(fa)的加(jia)工(gong)(gong)成本,完全取決于(yu)與壓型(xing)本身的耐用(yong)(yong)(yong)性-即使用(yong)(yong)(yong)壽(shou)命。壓型(xing)應(ying)能承受多(duo)次的重復操(cao)作使用(yong)(yong)(yong),包括劇烈的熱(re)沖擊(ji)及(ji)機械沖擊(ji)而不變形或損壞(huai)。良好(hao)的壓型(xing)及(ji)操(cao)作條件使壓鑄(zhu)能生產(chan)出(chu)的金屬鑄(zhu)件,要比用(yong)(yong)(yong)其他熱(re)加(jia)工(gong)(gong)成型(xing)方法(fa)生產(chan)的鑄(zhu)件,在尺寸精度和表面(mian)光潔度方面(mian)更好(hao)。

多年來,研究者力圖將(jiang)在(zai)(zai)低熔點結(jie)構金(jin)(jin)屬上獲(huo)得(de)應(ying)用(yong)成功(gong)的(de)(de)壓(ya)(ya)(ya)鑄(zhu)(zhu)(zhu)(zhu)法(fa),也應(ying)用(yong)于高熔點金(jin)(jin)屬的(de)(de)鑄(zhu)(zhu)(zhu)(zhu)造上。盡管(guan)壓(ya)(ya)(ya)型(xing)(xing)表(biao)面(mian)受(shou)(shou)到(dao)的(de)(de)熱(re)沖(chong)擊(ji)嚴(yan)重程(cheng)度不同,過早的(de)(de)產生龜裂或熱(re)裂,使(shi)(shi)壓(ya)(ya)(ya)型(xing)(xing)的(de)(de)使(shi)(shi)用(yong)性(xing)(xing)能(neng)(neng)(neng)(neng)受(shou)(shou)到(dao)限制,但(dan)某些黃(huang)銅及(ji)青銅零件(jian)現已能(neng)(neng)(neng)(neng)正式(shi)用(yong)壓(ya)(ya)(ya)鑄(zhu)(zhu)(zhu)(zhu)生產了。當然,壓(ya)(ya)(ya)型(xing)(xing)抵抗這種(zhong)破壞的(de)(de)能(neng)(neng)(neng)(neng)力,部分取決于鑄(zhu)(zhu)(zhu)(zhu)造金(jin)(jin)屬的(de)(de)溫度,例如,合金(jin)(jin)鋼(gang)壓(ya)(ya)(ya)型(xing)(xing)就(jiu)可以幾(ji)十萬次循環(huan)來生產鋅(xin)鑄(zhu)(zhu)(zhu)(zhu)件(jian),若對黃(huang)銅鑄(zhu)(zhu)(zhu)(zhu)件(jian)來說,就(jiu)只能(neng)(neng)(neng)(neng)用(yong)幾(ji)千(qian)次。壓(ya)(ya)(ya)鑄(zhu)(zhu)(zhu)(zhu)在(zai)(zai)高熔點鐵(tie)基(ji)金(jin)(jin)屬方面(mian)的(de)(de)應(ying)用(yong),集中在(zai)(zai)耐高溫的(de)(de)金(jin)(jin)屬鎢(wu)和鉬(mu)的(de)(de)形狀及(ji)大小(xiao)方面(mian),適于制造壓(ya)(ya)(ya)鑄(zhu)(zhu)(zhu)(zhu)的(de)(de)壓(ya)(ya)(ya)型(xing)(xing)之后才(cai)有(you)(you)可能(neng)(neng)(neng)(neng)。這些耐高溫的(de)(de)金(jin)(jin)屬及(ji)其合金(jin)(jin)具有(you)(you)非凡的(de)(de)熱(re)性(xing)(xing)能(neng)(neng)(neng)(neng)和機械(xie)性(xing)(xing)能(neng)(neng)(neng)(neng),使(shi)(shi)得(de)壓(ya)(ya)(ya)型(xing)(xing)能(neng)(neng)(neng)(neng)承(cheng)受(shou)(shou)鋼(gang)、鐵(tie)合金(jin)(jin)在(zai)(zai)壓(ya)(ya)(ya)鑄(zhu)(zhu)(zhu)(zhu)時特別嚴(yan)酷的(de)(de)熱(re)沖(chong)擊(ji)要(yao)求,從(cong)而(er)提高壓(ya)(ya)(ya)型(xing)(xing)的(de)(de)使(shi)(shi)用(yong)壽命(ming)。

早在20世紀70年代,壓鑄就被認為是不銹鋼及合金成型方面可采用的生產方法,尤其是當采用其他制造方法有困難或成本高的零件時,更是如此。現在黑色金屬壓鑄法在許多領域的應用與鍛造,精密鑄造以及用型材切削加工方面都處于競爭的地位。

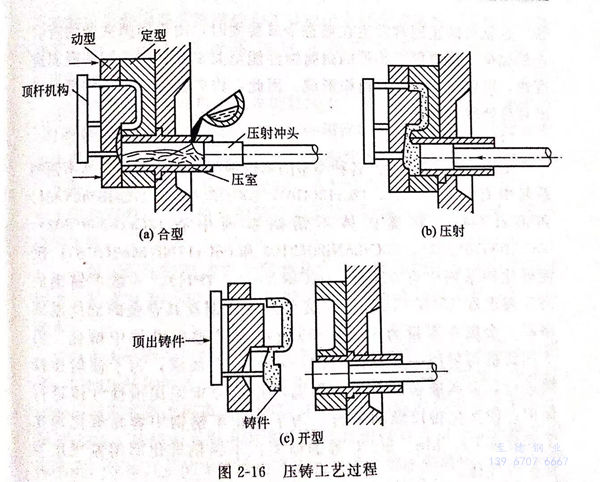

圖2-16是壓鑄工藝過程的示意圖。

1. 不銹鋼(gang)壓鑄(zhu)的優點(dian)

不(bu)銹鋼(gang)壓(ya)(ya)(ya)鑄(zhu)(zhu)(zhu)的一個重要的經濟(ji)優點是(shi)(shi)(shi),該法能利用(yong)(yong)(yong)廉價的不(bu)銹鋼(gang)廢料(liao)作為原料(liao)。用(yong)(yong)(yong)該方法鑄(zhu)(zhu)(zhu)造所產(chan)(chan)(chan)生(sheng)(sheng)(sheng)的廢料(liao)(如直澆道(dao)、橫澆道(dao)等)是(shi)(shi)(shi)非(fei)常清潔、純凈的,只要進(jin)一步加工(gong)處理,便可回收再用(yong)(yong)(yong)。此外(wai),金(jin)屬壓(ya)(ya)(ya)鑄(zhu)(zhu)(zhu)法,還可用(yong)(yong)(yong)來(lai)(lai)生(sheng)(sheng)(sheng)產(chan)(chan)(chan)一些(xie)不(bu)能直接從棒材或(huo)(huo)鍛坯制取合金(jin)零(ling)件;或(huo)(huo)者是(shi)(shi)(shi)它(ta)們的形狀(zhuang)不(bu)可能或(huo)(huo)難(nan)以用(yong)(yong)(yong)切削加工(gong)的方法加工(gong)的零(ling)部件。可是(shi)(shi)(shi),在(zai)生(sheng)(sheng)(sheng)產(chan)(chan)(chan)不(bu)銹鋼(gang)壓(ya)(ya)(ya)鑄(zhu)(zhu)(zhu)件的成本(ben)中,壓(ya)(ya)(ya)型(xing)的維(wei)修費用(yong)(yong)(yong)要比非(fei)鐵合金(jin)壓(ya)(ya)(ya)型(xing)鑄(zhu)(zhu)(zhu)件的大得多(duo)。甚至在(zai)最佳的情況下,用(yong)(yong)(yong)來(lai)(lai)生(sheng)(sheng)(sheng)產(chan)(chan)(chan)鋼(gang)鑄(zhu)(zhu)(zhu)件的耐高溫金(jin)屬壓(ya)(ya)(ya)型(xing)的壽(shou)命(ming)也遠(yuan)不(bu)如生(sheng)(sheng)(sheng)產(chan)(chan)(chan)鋁及鋅(xin)壓(ya)(ya)(ya)鑄(zhu)(zhu)(zhu)件壓(ya)(ya)(ya)型(xing)的使(shi)用(yong)(yong)(yong)壽(shou)命(ming)。經濟(ji)成本(ben)的另(ling)一問題是(shi)(shi)(shi),在(zai)生(sheng)(sheng)(sheng)產(chan)(chan)(chan)不(bu)銹鋼(gang)或(huo)(huo)高合金(jin)鋼(gang)壓(ya)(ya)(ya)鑄(zhu)(zhu)(zhu)件的費用(yong)(yong)(yong)中,相當大的一部分是(shi)(shi)(shi)用(yong)(yong)(yong)在(zai)壓(ya)(ya)(ya)型(xing)的維(wei)修費上。

金屬(shu)壓(ya)鑄(zhu)法適用(yong)于成(cheng)分范圍很(hen)廣的(de)(de)(de)合(he)金,從生產鑄(zhu)鐵(tie)到工具鋼(gang)零(ling)件(jian)。在(zai)黑色金屬(shu)中,不(bu)銹(xiu)鋼(gang)似乎最(zui)能(neng)提(ti)供(gong)發揮這(zhe)種方法的(de)(de)(de)最(zui)佳(jia)機會(hui),這(zhe)主要(yao)是(shi)由(you)(you)于不(bu)銹(xiu)鋼(gang)用(yong)壓(ya)鑄(zhu)方法比低(di)(di)合(he)金結構鋼(gang)易于成(cheng)型,容易獲得表面光潔度(du)(du)高(gao)及致密的(de)(de)(de)鑄(zhu)件(jian),而且(qie)壓(ya)型的(de)(de)(de)使用(yong)壽(shou)命較長(chang)。所(suo)(suo)有(you)這(zhe)些,被認為是(shi)由(you)(you)于不(bu)銹(xiu)鋼(gang)的(de)(de)(de)熱導(dao)率比低(di)(di)合(he)金結構鋼(gang)要(yao)低(di)(di)得多的(de)(de)(de)緣故(gu),此外,黑色金屬(shu)在(zai)用(yong)耐高(gao)溫壓(ya)型進行壓(ya)鑄(zhu)時,其凝(ning)固(gu)速度(du)(du)特別快,這(zhe)對鋼(gang)鑄(zhu)件(jian)的(de)(de)(de)結構和性(xing)能(neng)都有(you)一定的(de)(de)(de)好處。對不(bu)銹(xiu)鋼(gang)來說,最(zui)顯(xian)(xian)著的(de)(de)(de)效果就(jiu)是(shi)提(ti)高(gao)其耐腐蝕(shi)性(xing),因(yin)為壓(ya)鑄(zhu)的(de)(de)(de)凝(ning)固(gu)速度(du)(du)非(fei)常(chang)之快,這(zhe)就(jiu)可防(fang)止通常(chang)發生在(zai)液態金屬(shu)凝(ning)固(gu)時,由(you)(you)于間(jian)隙(xi)夾雜物所(suo)(suo)引(yin)起的(de)(de)(de)偏析,這(zhe)對提(ti)高(gao)鑄(zhu)件(jian)的(de)(de)(de)耐腐蝕(shi)性(xing)能(neng)至(zhi)關重要(yao)。由(you)(you)于鑄(zhu)件(jian)凝(ning)固(gu)速度(du)(du)快,可促(cu)使細(xi)的(de)(de)(de)晶粒組織(zhi)形成(cheng)。因(yin)此,許多鐵(tie)合(he)金壓(ya)鑄(zhu)件(jian)都顯(xian)(xian)示出(chu)對熱處理(li)的(de)(de)(de)敏感性(xing)。

2. 壓(ya)鑄工(gong)藝

壓(ya)(ya)鑄(zhu)工藝(yi)已用(yong)于生產各種類型的不銹鋼(gang)(gang)壓(ya)(ya)鑄(zhu)件(jian)。在(zai)(zai)(zai)馬氏體(ti)不銹鋼(gang)(gang)系列中(zhong)(zhong)有12Cr12(403),12Cr13(410),20Cr13(420),17Cr16Ni2(431)和68Cr17(440);在(zai)(zai)(zai)奧氏體(ti)不銹鋼(gang)(gang)系列中(zhong)(zhong)有12Cr18Ni9(302),06Cr19Ni10(304),20Cr25Ni20(310)和06Cr17Ni2Mo2(316);沉淀硬化(hua)鋼(gang)(gang)系列中(zhong)(zhong)有05Cr17Ni4Cu4Nb(17-4PH).一般不銹鋼(gang)(gang)的澆(jiao)注(zhu)溫(wen)度(du)在(zai)(zai)(zai)1500~1600℃,這個溫(wen)度(du)比銅及(ji)其(qi)合金(jin)(jin)的澆(jiao)注(zhu)溫(wen)度(du)略高。金(jin)(jin)屬在(zai)(zai)(zai)容量為200~300kg的無芯(xin)感應電爐中(zhong)(zhong)熔化(hua)。由于壓(ya)(ya)鑄(zhu)機(ji)每射壓(ya)(ya)一次(ci)只能澆(jiao)注(zhu)一小部分金(jin)(jin)屬液,為了使射壓(ya)(ya)持續進(jin)行(xing),金(jin)(jin)屬液必須在(zai)(zai)(zai)爐中(zhong)(zhong)保溫(wen),這就要求采(cai)用(yong)惰(duo)性氣體(ti)進(jin)行(xing)保護,使熔化(hua)得以順利進(jin)行(xing)。為了防止不銹鋼(gang)(gang)中(zhong)(zhong)容易氧化(hua)的化(hua)學成分如Cr、Mn、Si、C等(deng)的損失,不銹鋼(gang)(gang)熔化(hua)多用(yong)氮氣作為保護性氣體(ti)。

目前(qian),不銹鋼壓(ya)(ya)(ya)(ya)鑄(zhu)法(fa)仍采用(yong),手端澆包從(cong)附近的(de)(de)(de)熔爐(lu)中取出(chu)金(jin)屬(shu)液,對(dui)壓(ya)(ya)(ya)(ya)鑄(zhu)機進行金(jin)屬(shu)液的(de)(de)(de)澆注,這(zhe)與一般鋁(lv)合金(jin)壓(ya)(ya)(ya)(ya)鑄(zhu)的(de)(de)(de)生(sheng)產相(xiang)類似。操(cao)作(zuo)者用(yong)澆包從(cong)熔爐(lu)中取出(chu)金(jin)屬(shu)液,澆入壓(ya)(ya)(ya)(ya)鑄(zhu)機的(de)(de)(de)壓(ya)(ya)(ya)(ya)射(she)(she)系統(tong),然后按(an)動(dong)電鈕(niu),將金(jin)屬(shu)液壓(ya)(ya)(ya)(ya)射(she)(she)入壓(ya)(ya)(ya)(ya)型(xing)(xing)中。般射(she)(she)壓(ya)(ya)(ya)(ya)力(li)的(de)(de)(de)范圍(wei)為5000~15000psi(1psi=6894.76Pa)。金(jin)屬(shu)射(she)(she)入壓(ya)(ya)(ya)(ya)型(xing)(xing),在(zai)(zai)壓(ya)(ya)(ya)(ya)射(she)(she)系統(tong)的(de)(de)(de)作(zuo)用(yong)下(xia),不到1秒即可完成(cheng)。對(dui)一些相(xiang)當薄(從(cong)1~20mm)的(de)(de)(de)壓(ya)(ya)(ya)(ya)鑄(zhu)件(jian),實際在(zai)(zai)1秒內便開(kai)始(shi)凝固了。鑄(zhu)件(jian)在(zai)(zai)壓(ya)(ya)(ya)(ya)型(xing)(xing)中的(de)(de)(de)停(ting)留時間,即從(cong)金(jin)屬(shu)液射(she)(she)入到壓(ya)(ya)(ya)(ya)型(xing)(xing)開(kai)啟取出(chu)壓(ya)(ya)(ya)(ya)鑄(zhu)件(jian)之間的(de)(de)(de)時間間隔(ge)一般約2~4秒。為了防止“冷(leng)隔(ge)”和其(qi)他鑄(zhu)造缺(que)陷,以獲得表面光潔的(de)(de)(de)鑄(zhu)件(jian),壓(ya)(ya)(ya)(ya)型(xing)(xing)必須預熱(re),平均操(cao)作(zuo)溫度(du)要保持(chi)在(zai)(zai)幾百攝氏(shi)度(du),適宜的(de)(de)(de)溫度(du)取決于(yu)鑄(zhu)造金(jin)屬(shu)的(de)(de)(de)特性。在(zai)(zai)金(jin)屬(shu)射(she)(she)入壓(ya)(ya)(ya)(ya)型(xing)(xing)之前(qian),在(zai)(zai)壓(ya)(ya)(ya)(ya)型(xing)(xing)的(de)(de)(de)表面需要涂刷一層分型(xing)(xing)劑(ji),石墨是良好(hao)的(de)(de)(de)分型(xing)(xing)劑(ji),其(qi)作(zuo)用(yong)是改善表面的(de)(de)(de)光潔度(du),使射(she)(she)壓(ya)(ya)(ya)(ya)的(de)(de)(de)速度(du)更(geng)快,鑄(zhu)件(jian)的(de)(de)(de)光潔度(du)就越高。但(dan)是這(zhe)種情況通常是在(zai)(zai)犧(xi)牲鑄(zhu)件(jian)內部的(de)(de)(de)致密性和無疏松的(de)(de)(de)條件(jian)下(xia)獲得的(de)(de)(de)。在(zai)(zai)良好(hao)的(de)(de)(de)條件(jian)下(xia),奧氏(shi)體不銹鋼壓(ya)(ya)(ya)(ya)鑄(zhu)件(jian)的(de)(de)(de)鑄(zhu)態表面光潔度(du)可達到0.008~0.0013mm。

一個在現代(dai)壓鑄(zhu)(zhu)機上工(gong)作(zuo)(zuo)的(de)(de)熟(shu)練操作(zuo)(zuo)者,每小(xiao)時(shi)的(de)(de)生產率(lv)可(ke)達100件(jian)或更多。與其他鑄(zhu)(zhu)造工(gong)藝方法相比,壓鑄(zhu)(zhu)工(gong)藝每一個操作(zuo)(zuo)者的(de)(de)生產量要高得多,特(te)別是(shi)(shi)當采(cai)用多型(xing)(xing)腔(qiang)的(de)(de)壓型(xing)(xing)時(shi),更是(shi)(shi)如(ru)此。對于(yu)小(xiao)件(jian),壓鑄(zhu)(zhu)工(gong)藝的(de)(de)每一次操作(zuo)(zuo),這種(zhong)壓型(xing)(xing)可(ke)以(yi)同時(shi)包含10個以(yi)上不同的(de)(de)型(xing)(xing)腔(qiang),或是(shi)(shi)所有的(de)(de)型(xing)(xing)腔(qiang)都是(shi)(shi)同一種(zhong)零件(jian)或有關的(de)(de)同一類不同的(de)(de)零件(jian)。

一般壓(ya)鑄件(jian)(jian)的質量從幾克(ke)到幾千克(ke),鑄件(jian)(jian)的尺寸(cun)從小(xiao)于1cm到最長尺寸(cun)為20~30cm.鑄件(jian)(jian)的尺寸(cun)公差(cha)可達到每厘米百(bai)分之幾毫(hao)米。

由(you)于(yu)不銹鋼與壓(ya)型(xing)(xing)(xing)所用耐高溫合金的(de)熱膨脹系數有(you)(you)著(zhu)很(hen)大的(de)差(cha)別,因此壓(ya)鑄(zhu)(zhu)(zhu)件(jian)(jian)的(de)外表(biao)面(mian)(mian)在大多數情(qing)況下不需要拔(ba)(ba)模斜度,但鑄(zhu)(zhu)(zhu)件(jian)(jian)的(de)內(nei)表(biao)面(mian)(mian)則需要拔(ba)(ba)模斜度,即零件(jian)(jian)與芯(xin)子的(de)表(biao)面(mian)(mian)最少必須有(you)(you)5°~10°的(de)斜度。選擇相(xiang)當(dang)簡單的(de)零件(jian)(jian)可直(zhi)接由(you)帶有(you)(you)確定內(nei)腔(qiang)(qiang)(qiang)的(de)兩(liang)半壓(ya)型(xing)(xing)(xing)組成。比較復雜的(de)零件(jian)(jian)可由(you)帶有(you)(you)活動(dong)芯(xin)子的(de)壓(ya)型(xing)(xing)(xing)制得,或由(you)帶有(you)(you)空(kong)腔(qiang)(qiang)(qiang)的(de)具體部件(jian)(jian)組成。這(zhe)些(xie)部件(jian)(jian)通過壓(ya)鑄(zhu)(zhu)(zhu)機在兩(liang)半主要壓(ya)型(xing)(xing)(xing)開型(xing)(xing)(xing)之前(qian)由(you)鑄(zhu)(zhu)(zhu)件(jian)(jian)中(zhong)取(qu)(qu)出或同(tong)時(shi)(shi)取(qu)(qu)出。一般壓(ya)型(xing)(xing)(xing)都設計有(you)(you)輔助桿(頂(ding)(ding)出桿),當(dang)一個壓(ya)鑄(zhu)(zhu)(zhu)循環結束(shu)時(shi)(shi),壓(ya)鑄(zhu)(zhu)(zhu)機開啟壓(ya)型(xing)(xing)(xing),通過頂(ding)(ding)桿便很(hen)容易將壓(ya)鑄(zhu)(zhu)(zhu)件(jian)(jian)從壓(ya)型(xing)(xing)(xing)型(xing)(xing)(xing)腔(qiang)(qiang)(qiang)中(zhong)頂(ding)(ding)出。

3. 壓鑄(zhu)后(hou)處理

不銹鋼壓(ya)(ya)(ya)鑄(zhu)(zhu)件(jian)(jian)的直(zhi)澆道使(shi)用(yong)圓盤鋸(ju)或(huo)(huo)整形壓(ya)(ya)(ya)力(li)機(ji)(ji)加以切除。奧氏(shi)(shi)體(ti)不銹鋼件(jian)(jian)一(yi)(yi)般在(zai)(zai)壓(ya)(ya)(ya)鑄(zhu)(zhu)后不需要(yao)進(jin)行(xing)熱處(chu)(chu)理,因為壓(ya)(ya)(ya)鑄(zhu)(zhu)后的零(ling)件(jian)(jian)具(ju)有足夠(gou)的強(qiang)度(du)和(he)韌性。馬氏(shi)(shi)體(ti)不銹鋼鑄(zhu)(zhu)件(jian)(jian),如12Cr12(403)、12Cr13(410)、17Cr16Ni2(431)等,往(wang)往(wang)在(zai)(zai)壓(ya)(ya)(ya)鑄(zhu)(zhu)后可能超過需要(yao)的硬(ying)度(du),特別是當(dang)碳的含量接近或(huo)(huo)超過一(yi)(yi)定限度(du)時(shi),更是如此。所(suo)以,這(zhe)類零(ling)件(jian)(jian)需要(yao)進(jin)行(xing)回火(huo)或(huo)(huo)退火(huo)處(chu)(chu)理以降低硬(ying)度(du),提高韌性。最后鑄(zhu)(zhu)件(jian)(jian)根據不同使(shi)用(yong)場合(he),應(ying)用(yong)清(qing)理滾筒(tong)、振動拋(pao)光機(ji)(ji)、砂輪磨(mo)光機(ji)(ji)等常用(yong)方法進(jin)行(xing)清(qing)理。一(yi)(yi)般零(ling)件(jian)(jian)的內部詳(xiang)細形狀不容易壓(ya)(ya)(ya)鑄(zhu)(zhu)出來,例如螺紋孔等,就需要(yao)對壓(ya)(ya)(ya)鑄(zhu)(zhu)件(jian)(jian)進(jin)行(xing)切削加工(gong)獲得的。一(yi)(yi)般用(yong)壓(ya)(ya)(ya)鑄(zhu)(zhu)法生產的不銹鋼零(ling)件(jian)(jian)的清(qing)理工(gong)作量要(yao)比(bi)鍛造和(he)砂型(xing)鑄(zhu)(zhu)造所(suo)花的清(qing)理工(gong)作量小得多。