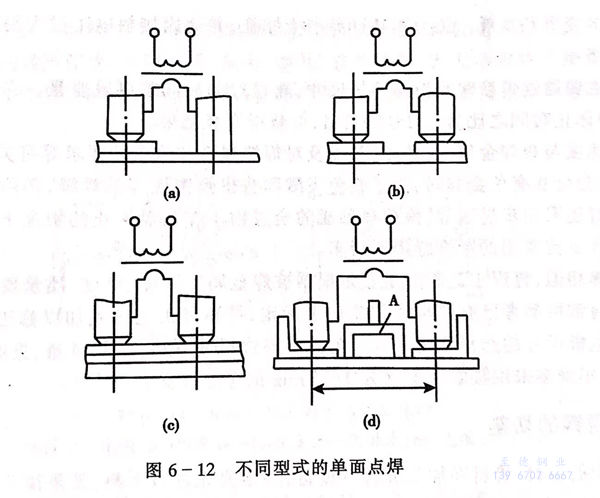

點焊工件只在有限的接觸面上即所謂“點”上被焊接起來,并形成扁球形的熔核。點焊又分為單點焊和多點焊,多點焊時使用兩對以上的電極,在同一工序內形成多個熔核。點焊方法通常又分為雙面點焊和單面點焊兩大類。雙面點焊時,通常采用搭接接頭和折邊接頭兩種形式(圖6-11).接頭可以由兩個或兩個以上等厚度或不等厚度的工件組成。在設計點焊結構時,必須考慮電極的可達性,即電極必須能方便地抵達構件的焊接部位。同時還應考慮邊距、搭接量、點距、裝配間隔和焊點強度等因素。

由于不(bu)銹鋼(gang)的電阻率高、導熱性差,因此與低碳鋼相比,可采用較小的焊接電流和較短的焊接時間。不銹鋼有較高的高溫強度,必須采用較高的電極壓力,以防止產生縮孔、裂紋等缺陷。不銹鋼的熱敏感性強,通常采用較短的焊接時間、強有力的內部和外部水冷卻,并且要準確地控制加熱時間和焊接電流,以防熱影響區晶粒長大和出現晶間腐蝕現象。點焊不銹鋼的電極推薦用硬度較高的電極合金,滿足高電極壓力的需要。

馬氏體不銹(xiu)鋼由于有(you)淬火(huo)傾向,點焊時要求采(cai)用較長(chang)焊接時間(jian)。為(wei)消(xiao)除淬硬組織,最好采(cai)用焊后回(hui)火(huo)的雙脈沖(chong)點焊。點焊時一般(ban)不采(cai)用電極的外部(bu)水冷卻,以免因(yin)淬火(huo)而(er)產生裂紋。

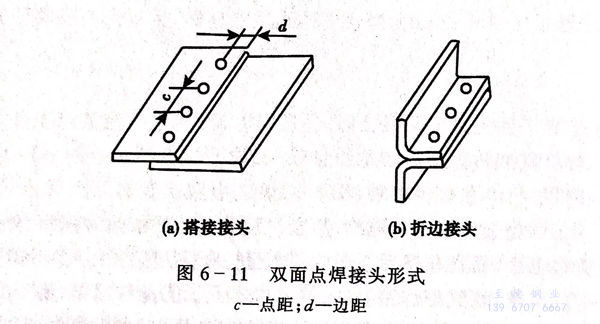

單(dan)(dan)面(mian)(mian)點(dian)(dian)(dian)焊(han)(han)(han)(han)時,電(dian)(dian)(dian)(dian)(dian)極(ji)由工(gong)件(jian)的(de)(de)(de)同一側向焊(han)(han)(han)(han)接(jie)處(chu)饋電(dian)(dian)(dian)(dian)(dian)。典(dian)型的(de)(de)(de)單(dan)(dan)面(mian)(mian)點(dian)(dian)(dian)焊(han)(han)(han)(han)方式如(ru)圖6-12所示。圖中:(a)單(dan)(dan)面(mian)(mian)單(dan)(dan)點(dian)(dian)(dian)點(dian)(dian)(dian)焊(han)(han)(han)(han),不形成焊(han)(han)(han)(han)點(dian)(dian)(dian)的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)極(ji)采用大(da)(da)直徑和(he)大(da)(da)接(jie)觸(chu)面(mian)(mian)以(yi)減(jian)小電(dian)(dian)(dian)(dian)(dian)流(liu)密度。(b)無分(fen)流(liu)的(de)(de)(de)單(dan)(dan)面(mian)(mian)雙點(dian)(dian)(dian)點(dian)(dian)(dian)焊(han)(han)(han)(han),此時焊(han)(han)(han)(han)接(jie)電(dian)(dian)(dian)(dian)(dian)流(liu)全部流(liu)經焊(han)(han)(han)(han)接(jie)區。(c)有(you)分(fen)流(liu)的(de)(de)(de)單(dan)(dan)面(mian)(mian)雙點(dian)(dian)(dian)點(dian)(dian)(dian)焊(han)(han)(han)(han),流(liu)經上面(mian)(mian)工(gong)件(jian)的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)流(liu)不經過(guo)焊(han)(han)(han)(han)接(jie)區,形成分(fen)流(liu)。為了(le)(le)給焊(han)(han)(han)(han)接(jie)電(dian)(dian)(dian)(dian)(dian)流(liu)提供(gong)低電(dian)(dian)(dian)(dian)(dian)阻(zu)的(de)(de)(de)通路。在工(gong)件(jian)下面(mian)(mian)墊(dian)(dian)有(you)銅(tong)墊(dian)(dian)板(ban)。(d)當(dang)兩(liang)焊(han)(han)(han)(han)點(dian)(dian)(dian)的(de)(de)(de)間距很大(da)(da),如(ru)在進(jin)行骨架構件(jian)和(he)復(fu)板(ban)的(de)(de)(de)焊(han)(han)(han)(han)接(jie)時,為了(le)(le)避免(mian)不適當(dang)的(de)(de)(de)加熱(re)引起翹曲和(he)減(jian)小兩(liang)電(dian)(dian)(dian)(dian)(dian)極(ji)間電(dian)(dian)(dian)(dian)(dian)阻(zu),采用了(le)(le)特殊的(de)(de)(de)銅(tong)橋(qiao)A,與電(dian)(dian)(dian)(dian)(dian)極(ji)同時壓緊在工(gong)件(jian)上。