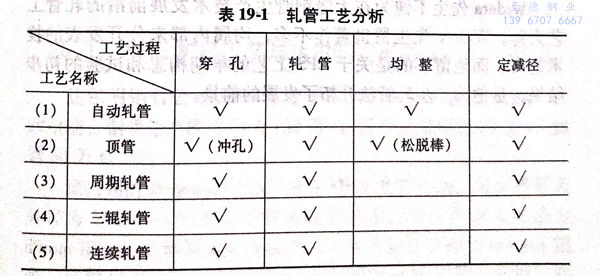

不銹鋼管廠家按工藝流程長、短對軋管工藝的分析如表19-1所示。通常所講的二步或三步軋管法是就變形階段而言的,具有“穿孔、軋管(延伸)和精軋”三個變形階段的軋管工藝就是三步軋管法;如表19-1所列(4)、(5)兩種軋管工藝。若省去穿孔或軋管兩個變形階段的任何一個即成為二步管法。屬于短流程范疇,而表中所列的(1)、(2)、(3)三種工藝,因為多了均整,延伸工序,比三步軋管法還多了一步,那就是長流程了。

兩(liang)步軋(ya)管(guan)法有采用連鑄空心坯軋(ya)管(guan)和采用CPS工藝兩(liang)種工藝。

CPS工(gong)(gong)(gong)藝(yi)是(shi)(shi)一(yi)種二步(bu)軋管(guan)(guan)工(gong)(gong)(gong)藝(yi),“CP”兩字(zi)代(dai)表(biao)(biao)(biao)Cross-Rolling Piercing,“S”代(dai)表(biao)(biao)(biao)“Stretch Reducing”,合起(qi)來(lai)即“斜(xie)軋穿孔-張(zhang)減(jian)法(fa)”。從TOSA鋼管(guan)(guan)廠的實際來(lai)看(kan),這(zhe)一(yi)工(gong)(gong)(gong)藝(yi)并不成功,從變形(xing)理論的角度(du)來(lai)看(kan),可(ke)能找不到什么(me)原因;從技術角度(du)看(kan)是(shi)(shi)因為管(guan)(guan)子內表(biao)(biao)(biao)面質量(liang)欠佳(jia)且無法(fa)控(kong)制或(huo)改(gai)善;有人說與(yu)Wider先(xian)生在南非(fei)出車禍(huo)身亡有關。CPS工(gong)(gong)(gong)藝(yi)失敗的原因至(zhi)今還是(shi)(shi)個謎,但(dan)從軋管(guan)(guan)工(gong)(gong)(gong)藝(yi)不斷(duan)地發(fa)展(zhan)這(zhe)一(yi)點來(lai)看(kan),遲早(zao)會(hui)弄。精楚(chu)的。

CPS軋管(guan)工(gong)(gong)(gong)(gong)藝(yi)(yi)(yi)是劃時代的技(ji)術(shu)發展(zhan),其含義在于可以實(shi)現(xian)(xian)沒有軋管(guan)機的軋管(guan)生(sheng)產,這(zhe)是曼(man)內斯曼(man)兄弟二(er)步軋管(guan)法在另(ling)一(yi)種形過(guo)下(xia)的再生(sheng),但這(zhe)種工(gong)(gong)(gong)(gong)藝(yi)(yi)(yi)僅僅是出現(xian)(xian)過(guo),“活”了(le)1年(nian)零(ling)4個月(yue),而沒有完全復(fu)活,作(zuo)為(wei)曼(man)內斯曼(man)公司的工(gong)(gong)(gong)(gong)藝(yi)(yi)(yi)負責人,Wider過(guo)為(wei)了(le)在南非TOSA為(wei)廠(chang)進(jin)行(xing)CPS工(gong)(gong)(gong)(gong)藝(yi)(yi)(yi)的工(gong)(gong)(gong)(gong)業(ye)性試(shi)驗,遠涉重(zhong)洋,前往約翰內斯堡(bao),按他提出的試(shi)軋方案進(jin)行(xing)了(le)為(wei)時一(yi)年(nian)的試(shi)驗,從TOSA廠(chang)的生(sheng)產實(shi)際來看(kan),這(zhe)一(yi)工(gong)(gong)(gong)(gong)藝(yi)(yi)(yi)試(shi)驗未獲成(cheng)功(gong),而Widera 先(xian)生(sheng)也赍(ji)志而歿,魂(hun)歸(gui)南非了(le)!

不(bu)銹鋼管(guan)廠家在生(sheng)(sheng)產技術(shu)發(fa)展(zhan)前沿的(de)(de)軋(ya)管(guan)工藝(yi)大(da)師,Widera先生(sheng)(sheng)留世著作不(bu)多,均(jun)屬內部未公開發(fa)表(biao)的(de)(de)技術(shu)論文,而他留下的(de)(de)是關于(yu)CPS工藝(yi)的(de)(de)早期構(gou)思和試驗(yan)的(de)(de)初步結果,是他為二步軋(ya)管(guan)法(fa)開拓了發(fa)展(zhan)的(de)(de)前景。