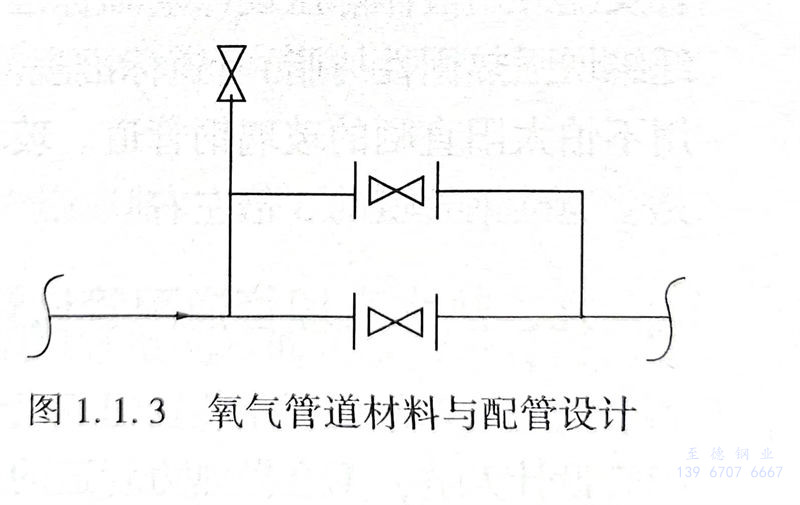

在某石化裝置,浙江至德鋼業有限公司工人人員發現某氧氣管道閥門側面還設計了防爆操作防護墻,有些防護過度。歸根結底是配管設計人員沒有真正理解標準規范的設計要求,由心中過度害怕引起。如圖1.1.3所示,某氧氣管道主管是18”的A312 TP304/TP304L(SMLS),后增加了旁路,配管設計人員仍選用A312 TP304/TP304L(SMLS)不銹鋼管(guan)道(dao)是錯誤的,因按照此工藝圖,旁路1.5"的流速加大了,需要選用鎳基合(he)金材料(UNS N06600)才可以滿足工程設計質量。氧氣管道材料應根據管道壓力、溫度和流速不同選用碳鋼、不銹鋼(gang)和鎳基合金;宜采用無縫鋼管、無縫管件、全通徑閥,其操作狀態全開或全關,不得使其處于半開半關狀態;切斷閥操作過程兩端壓差不能過大,閥門宜用法蘭連接;墊片宜選用帶內環聚四氟乙烯纏繞墊片;填料不應采用易脫落碎屑、纖維的材料或可燃的材料制成,宜選用聚四氟乙烯材料;三通宜選用等徑三通,氧氣管子、管件、閥門等應進行脫脂處理。見歐洲工業氣體協會標準(EIGA)《Oxygen Piping Systems》(氧氣管道系統)IGC DOC 13/12/E等規范。

如圖1.1.3所示,緊(jin)急切(qie)斷閥(fa)(fa)(fa)(fa)通(tong)(tong)(tong)(tong)常是自動的(de)(de)(de)(de),在全開(kai)位(wei)置(zhi)運行,通(tong)(tong)(tong)(tong)常僅在緊(jin)急情況下關閉。緊(jin)急切(qie)斷閥(fa)(fa)(fa)(fa)是高(gao)流(liu)量閥(fa)(fa)(fa)(fa),通(tong)(tong)(tong)(tong)常為(wei)(wei)(wei)閘閥(fa)(fa)(fa)(fa)、刀形閘閥(fa)(fa)(fa)(fa)、蝶閥(fa)(fa)(fa)(fa)或球閥(fa)(fa)(fa)(fa)。旁(pang)(pang)通(tong)(tong)(tong)(tong)閥(fa)(fa)(fa)(fa)通(tong)(tong)(tong)(tong)常是從(cong)手(shou)動閥(fa)(fa)(fa)(fa)的(de)(de)(de)(de)上游到下游的(de)(de)(de)(de)隔離閥(fa)(fa)(fa)(fa),安(an)裝目的(de)(de)(de)(de)是通(tong)(tong)(tong)(tong)過隔離閥(fa)(fa)(fa)(fa)對(dui)壓力進(jin)行均衡,一旦(dan)建立了壓力均衡,隔離閥(fa)(fa)(fa)(fa)可(ke)以安(an)全打(da)開(kai)。旁(pang)(pang)通(tong)(tong)(tong)(tong)閥(fa)(fa)(fa)(fa)也用(yong)于對(dui)下游系統緩慢加(jia)壓,以緩解超速和快速增壓風險。受控(kong)、緩慢加(jia)壓需(xu)要使用(yong)節(jie)流(liu)流(liu)量控(kong)制(zhi)型閥(fa)(fa)(fa)(fa)門,由于其(qi)具有流(liu)量控(kong)制(zhi)功(gong)能,旁(pang)(pang)通(tong)(tong)(tong)(tong)閥(fa)(fa)(fa)(fa)分(fen)為(wei)(wei)(wei)節(jie)流(liu)閥(fa)(fa)(fa)(fa)、過程控(kong)制(zhi)閥(fa)(fa)(fa)(fa)。雖然被歸類為(wei)(wei)(wei)過程控(kong)制(zhi)閥(fa)(fa)(fa)(fa),旁(pang)(pang)通(tong)(tong)(tong)(tong)閥(fa)(fa)(fa)(fa)通(tong)(tong)(tong)(tong)常為(wei)(wei)(wei)手(shou)動操作閥(fa)(fa)(fa)(fa),通(tong)(tong)(tong)(tong)常是截止閥(fa)(fa)(fa)(fa)或球閥(fa)(fa)(fa)(fa)等。為(wei)(wei)(wei)盡量減(jian)少旁(pang)(pang)通(tong)(tong)(tong)(tong)管線中(zhong)可(ke)能聚集的(de)(de)(de)(de)顆粒數量,旁(pang)(pang)通(tong)(tong)(tong)(tong)管連(lian)接應安(an)裝到主管中(zhong)心線或中(zhong)心線以上。

按GB 50030《氧氣(qi)站(zhan)設(she)(she)(she)計(ji)規范》,設(she)(she)(she)計(ji)壓(ya)力(li)大(da)(da)于(yu)(yu)0.1MPa的(de)氧氣(qi)管道上,不(bu)得用閘閥(fa)。設(she)(she)(she)計(ji)壓(ya)力(li)大(da)(da)于(yu)(yu)或等(deng)(deng)于(yu)(yu)1.0MPa且公稱直(zhi)徑(jing)大(da)(da)于(yu)(yu)或等(deng)(deng)于(yu)(yu)150mm的(de)氧氣(qi)管道上的(de)手動(dong)閥(fa)門,宜設(she)(she)(she)旁通閥(fa)。設(she)(she)(she)計(ji)壓(ya)力(li)大(da)(da)于(yu)(yu)1.0MPa,公稱直(zhi)徑(jing)大(da)(da)于(yu)(yu)或等(deng)(deng)于(yu)(yu)150mm的(de)氧氣(qi)管道上經常操作的(de)閥(fa)門,宜用氣(qi)動(dong)閥(fa)門。