鎢(wu)極(ji)氬弧(hu)焊(han)(han)(han)雖然能(neng)獲(huo)得優良(liang)的(de)(de)焊(han)(han)(han)接(jie)質量,但(dan)由于(yu)受(shou)到鎢(wu)極(ji)許用電流(liu)(liu)的(de)(de)限制,焊(han)(han)(han)接(jie)電流(liu)(liu)不能(neng)用得太大。一(yi)般情況下(xia),不開坡口對(dui)接(jie)鎢(wu)極(ji)氬弧(hu)焊(han)(han)(han)時,可以焊(han)(han)(han)透厚度小于(yu)3mm的(de)(de)母材,超過此厚度的(de)(de)焊(han)(han)(han)件如要全焊(han)(han)(han)透,需(xu)對(dui)母材開坡口。由于(yu)鎢(wu)極(ji)氬弧(hu)焊(han)(han)(han)焊(han)(han)(han)接(jie)速度慢(man),導致焊(han)(han)(han)接(jie)變形(xing)增加、焊(han)(han)(han)接(jie)接(jie)頭抗(kang)腐蝕性能(neng)下(xia)降,而且鎢(wu)極(ji)氬弧(hu)焊(han)(han)(han)焊(han)(han)(han)接(jie)時產生一(yi)定量的(de)(de)放(fang)射(she)線對(dui)人體(ti)有一(yi)定的(de)(de)損害,因(yin)此焊(han)(han)(han)接(jie)中、厚板奧氏體(ti)不銹鋼時已不能(neng)很(hen)好的(de)(de)滿足實(shi)際生產的(de)(de)需(xu)求(qiu)。

熔(rong)(rong)化(hua)極(ji)氣體保護焊(han)(han)(han)(han)用(yong)焊(han)(han)(han)(han)絲作為電極(ji)(和填充(chong)金屬),焊(han)(han)(han)(han)接電流可以大大提(ti)(ti)高。由于熔(rong)(rong)深大,焊(han)(han)(han)(han)絲熔(rong)(rong)敷速度快,提(ti)(ti)高了(le)生產效率(lv),改(gai)善了(le)勞(lao)動條件,減少了(le)焊(han)(han)(han)(han)接變形,同時(shi)還有利于提(ti)(ti)高焊(han)(han)(han)(han)接接頭耐腐蝕性能。熔(rong)(rong)化(hua)極(ji)氣體保護焊(han)(han)(han)(han)適用(yong)于中等和大厚度母材的焊(han)(han)(han)(han)接。

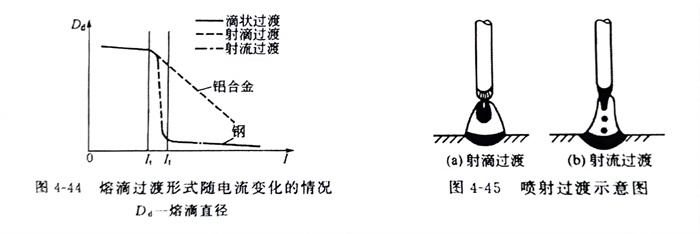

熔(rong)(rong)(rong)化(hua)極(ji)氣(qi)體保護焊(han)(han)(han)(han),是(shi)用(yong)可(ke)熔(rong)(rong)(rong)化(hua)的(de)(de)焊(han)(han)(han)(han)絲(si)與(yu)被焊(han)(han)(han)(han)工件之間的(de)(de)電(dian)弧作(zuo)為熱源來熔(rong)(rong)(rong)化(hua)焊(han)(han)(han)(han)絲(si)和(he)母材金屬,并(bing)向焊(han)(han)(han)(han)接區輸(shu)送(song)保護氣(qi)體,使電(dian)弧、熔(rong)(rong)(rong)化(hua)的(de)(de)焊(han)(han)(han)(han)絲(si)、熔(rong)(rong)(rong)池(chi)及附近(jin)金屬免(mian)受周圍(wei)空(kong)氣(qi)的(de)(de)有害作(zuo)用(yong),通過(guo)連續送(song)進焊(han)(han)(han)(han)絲(si)不斷熔(rong)(rong)(rong)化(hua)并(bing)過(guo)渡到熔(rong)(rong)(rong)池(chi),形成焊(han)(han)(han)(han)縫金屬。熔(rong)(rong)(rong)化(hua)極(ji)氣(qi)體保護焊(han)(han)(han)(han)焊(han)(han)(han)(han)接奧(ao)氏(shi)體型不銹鋼時(shi)的(de)(de)熔(rong)(rong)(rong)滴過(guo)渡有滴狀(zhuang)過(guo)渡、短路過(guo)渡和(he)噴(pen)射(she)過(guo)渡3種。其中滴狀(zhuang)過(guo)渡時(shi),熔(rong)(rong)(rong)滴直徑比(bi)焊(han)(han)(han)(han)絲(si)直徑大,飛濺較(jiao)(jiao)大,導致焊(han)(han)(han)(han)接過(guo)程不穩定(ding),在生產(chan)上極(ji)少使用(yong)。短路過(guo)渡電(dian)弧間隙小,電(dian)弧電(dian)壓較(jiao)(jiao)低,電(dian)弧功(gong)率(lv)比(bi)較(jiao)(jiao)小,適(shi)用(yong)于薄(bo)板焊(han)(han)(han)(han)接。生產(chan)中應用(yong)最(zui)為廣泛(fan)的(de)(de)是(shi)噴(pen)射(she)過(guo)渡,對于一定(ding)的(de)(de)焊(han)(han)(han)(han)絲(si)和(he)保護氣(qi)體,當焊(han)(han)(han)(han)接電(dian)流增大到臨界(jie)電(dian)流值時(shi)(圖(tu)4-44),焊(han)(han)(han)(han)絲(si)端(duan)頭熔(rong)(rong)(rong)化(hua)的(de)(de)金屬被壓縮成筆(bi)尖狀(zhuang),以細(xi)小熔(rong)(rong)(rong)滴從液柱尖端(duan)高速軸(zhou)向射(she)入熔(rong)(rong)(rong)池(chi),即噴(pen)射(she)過(guo)渡,如圖(tu)4-45所示。