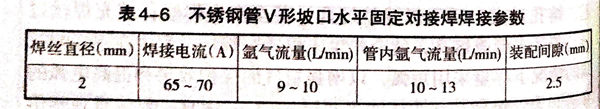

浙江至德鋼業有限公司 Φ57mm×4mm不(bu)銹鋼管 V形坡口水平固定對接焊焊接參數選用見表4-6。

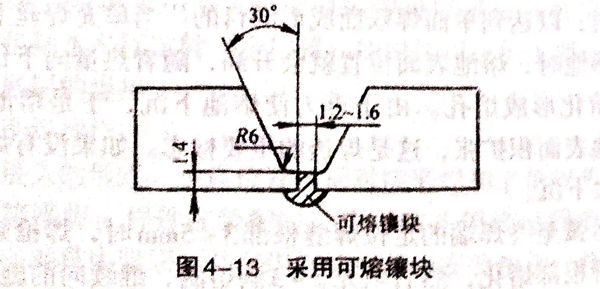

由于不銹鋼管內部很難設置(zhi)墊板,為保證(zheng)焊(han)縫根部質量(liang),可(ke)(ke)采(cai)用(yong)可(ke)(ke)熔鑲(xiang)塊。采(cai)用(yong)可(ke)(ke)熔鑲(xiang)塊時的坡口形(xing)式及尺寸如圖4-13所示。

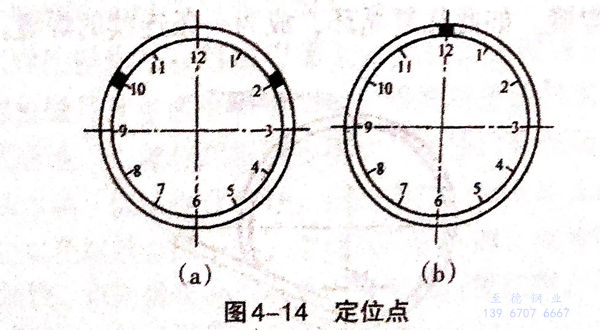

不銹鋼(gang)管(guan)裝配留好預定(ding)(ding)間(jian)隙后,在(zai)管(guan)子圓周(zhou)的時鐘位(wei)置2點(dian)和10點(dian)兩處焊接(jie)定(ding)(ding)位(wei)焊縫(圖4-14(a))或在(zai)時鐘12點(dian)處一點(dian)定(ding)(ding)位(wei)(圖4-14(b)).定(ding)(ding)位(wei)焊縫長度5~10mm,厚度3mm左右,定(ding)(ding)位(wei)焊縫要(yao)求焊透,將(jiang)成為正(zheng)式焊縫的一部分。定(ding)(ding)位(wei)焊縫不允許(xu)存在(zai)氣孔(kong)、夾渣、夾鎢、未焊透、未熔合(he)、裂紋等焊接(jie)缺陷,否則應把定(ding)(ding)位(wei)焊縫打(da)磨(mo)掉,重新(xin)定(ding)(ding)位(wei)。

定(ding)位(wei)焊(han)(han)(han)(han)縫的(de)焊(han)(han)(han)(han)接(jie)(jie)有兩種(zhong)手法(fa):第(di)(di)一(yi)種(zhong)是(shi)用(yong)斷續填(tian)(tian)(tian)絲(si)法(fa),在管子(zi)的(de)一(yi)側(ce)坡(po)口(kou)(kou)面上引弧(hu),再把電(dian)弧(hu)拉(la)至始(shi)(shi)焊(han)(han)(han)(han)部(bu)位(wei),焊(han)(han)(han)(han)槍(qiang)(qiang)做(zuo)橫向擺動,待根部(bu)熔(rong)(rong)化(hua)出現熔(rong)(rong)孔時(shi),在左(zuo)右側(ce)根部(bu)交替填(tian)(tian)(tian)充(chong)一(yi)滴(di)熔(rong)(rong)滴(di),焊(han)(han)(han)(han)絲(si)隨著焊(han)(han)(han)(han)槍(qiang)(qiang)的(de)擺動,斷續地、有節奏(zou)地向熔(rong)(rong)池(chi)前沿填(tian)(tian)(tian)充(chong),達到一(yi)定(ding)長(chang)度后,在坡(po)口(kou)(kou)面的(de)一(yi)側(ce)收弧(hu);第(di)(di)二種(zhong)是(shi)用(yong)連續填(tian)(tian)(tian)絲(si)法(fa),在一(yi)側(ce)坡(po)口(kou)(kou)面處引弧(hu),然(ran)后把電(dian)弧(hu)拉(la)至始(shi)(shi)焊(han)(han)(han)(han)部(bu)位(wei),焊(han)(han)(han)(han)槍(qiang)(qiang)做(zuo)橫向擺動,待引弧(hu)處金屬熔(rong)(rong)化(hua)時(shi),連續填(tian)(tian)(tian)絲(si)進(jin)行焊(han)(han)(han)(han)接(jie)(jie)。焊(han)(han)(han)(han)絲(si)端部(bu)的(de)熔(rong)(rong)滴(di)始(shi)(shi)終與熔(rong)(rong)池(chi)相連,達到一(yi)定(ding)長(chang)度后,在坡(po)口(kou)(kou)面的(de)一(yi)側(ce)收弧(hu)。

焊接不(bu)銹(xiu)鋼管必須向管內通氬氣,以防止反面合金元素氧化、燒損,降低耐腐蝕性。一種管子焊接的充氬裝置是:在管子的兩端加上端蓋,端蓋上用彈簧鋼絲把端蓋固定在管子的兩端,形成管子內部保護腔。進氣端的端蓋上設一氣閥,與氬氣瓶相連,氬氣從側面充入管內;在出氣端的端蓋上鉆一個直徑2mm的小孔(側面),以便氣體流出。

焊(han)前(qian)必須(xu)提起向不銹鋼管內通(tong)氬(ya)氣(qi),要(yao)待(dai)管內空氣(qi)完全排除(chu)后(hou)再焊(han)接。焊(han)接過程(cheng)中要(yao)不停地向管內通(tong)氬(ya)氣(qi),焊(han)縫(feng)即(ji)將封閉時,關斷氬(ya)氣(qi)源。

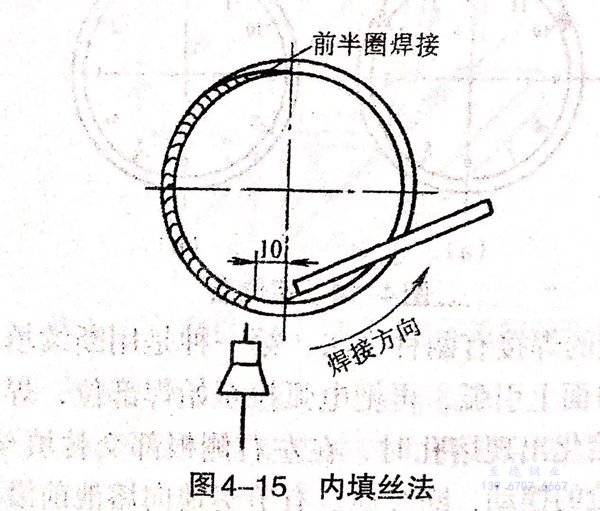

打(da)底焊(han)(han)(han)(han)時,為了保證焊(han)(han)(han)(han)縫根部(bu)的(de)質(zhi)量,通常采用內填(tian)絲(si)(si)法焊(han)(han)(han)(han)接(jie),將(jiang)焊(han)(han)(han)(han)絲(si)(si)從(cong)接(jie)頭(tou)裝配間隙中穿入不銹(xiu)鋼管(guan)內部(bu)填(tian)絲(si)(si),如圖4-15所示。焊(han)(han)(han)(han)絲(si)(si)在一側(ce)坡(po)(po)口(kou)面上引弧,然后把(ba)電弧移至時鐘6點位(wei)置,待坡(po)(po)口(kou)根部(bu)熔(rong)(rong)化出(chu)現熔(rong)(rong)孔(kong)時,左右兩(liang)側(ce)各填(tian)充一滴(di)(di)熔(rong)(rong)滴(di)(di),當這兩(liang)滴(di)(di)熔(rong)(rong)滴(di)(di)連(lian)在一起(qi),在熔(rong)(rong)池(chi)前方出(chu)現熔(rong)(rong)孔(kong),此時隨即將(jiang)焊(han)(han)(han)(han)絲(si)(si)緊貼根部(bu)填(tian)充一滴(di)(di)熔(rong)(rong)滴(di)(di),焊(han)(han)(han)(han)槍略做橫向擺(bai)動(dong),使(shi)焊(han)(han)(han)(han)絲(si)(si)填(tian)充的(de)熔(rong)(rong)滴(di)(di)熔(rong)(rong)合在一起(qi),成為焊(han)(han)(han)(han)縫。如此往復(fu)循環,成為一條連(lian)續的(de)焊(han)(han)(han)(han)縫。

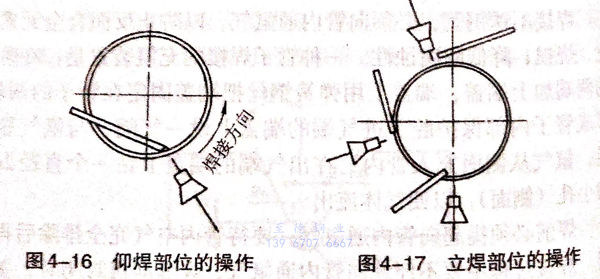

仰焊(han)部位的操作如(ru)圖4-16所(suo)示。

為了避免在仰焊(han)(han)部位焊(han)(han)縫反(fan)面產生內凹(ao),焊(han)(han)絲(si)要緊貼熔合處的根部,使焊(han)(han)絲(si)直接送入(ru)管子內壁。

立(li)焊部位(wei)的操作如圖4-17所示(shi)。

此時(shi)焊槍和(he)焊絲沿著管(guan)壁逐(zhu)漸往上移動,焊絲端部(bu)只要(yao)填充到熔(rong)合根部(bu)即可。

焊至爬坡焊部位時,由于管(guan)子溫(wen)度已經很高,因此,應(ying)將焊絲端(duan)部稍微(wei)離開熔(rong)合根部,以免反面(mian)焊縫產生焊瘤(liu)。

焊(han)(han)(han)至距定(ding)位焊(han)(han)(han)縫根部3~5mm時,為了保證接頭焊(han)(han)(han)透,焊(han)(han)(han)槍應畫個(ge)圈,把定(ding)位焊(han)(han)(han)縫根部熔化,但不填焊(han)(han)(han)絲,施(shi)焊(han)(han)(han)10mm左右在(zai)一側坡口面收弧。

管子后半(ban)(ban)圈的操作與前半(ban)(ban)圈相同。

蓋面焊(han)(han)的(de)操(cao)作(zuo)是在打(da)底焊(han)(han)道(dao)(dao)上引弧后(hou),于時(shi)(shi)鐘(zhong)6點位置(zhi)開始(shi)起焊(han)(han),焊(han)(han)槍做月牙形或(huo)鋸齒形擺動(dong),將坡口(kou)邊(bian)緣打(da)底焊(han)(han)道(dao)(dao)表面熔(rong)化,形成熔(rong)池。焊(han)(han)絲與焊(han)(han)槍同步(bu)擺動(dong),在坡口(kou)兩(liang)側稍作(zuo)停頓(dun),各稍加一滴(di)熔(rong)滴(di),保證熔(rong)合良(liang)好。在仰焊(han)(han)部位每(mei)次填充(chong)(chong)的(de)金屬要適當(dang)(dang)少(shao)些,以(yi)免熔(rong)敷金屬下墜。立焊(han)(han)部位操(cao)作(zuo)時(shi)(shi),焊(han)(han)槍的(de)擺動(dong)頻率要適當(dang)(dang)加快,以(yi)防熔(rong)化金屬下淌(tang)。平焊(han)(han)部位操(cao)作(zuo)時(shi)(shi),每(mei)次填充(chong)(chong)的(de)金屬要多(duo)些,以(yi)防平焊(han)(han)部位焊(han)(han)縫不(bu)飽滿。

收弧時采用電流衰減法收弧。蓋面焊縫封閉后,要繼續向前施焊10mm左右,并逐漸減少焊絲的填充量,以免收弧部位產生弧坑裂紋和縮孔,并且氬氣流的冷卻作用有助于防止產生晶間腐蝕(shi)。