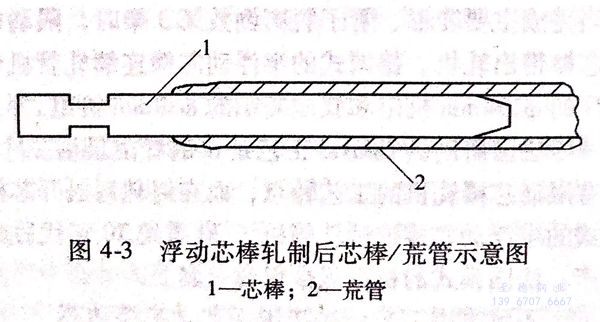

全浮動芯棒連續軋管機簡稱MM(Mandrel Mill),一般設有8個機架。軋制過程中對芯棒速度不加以控制,芯棒由被輾軋金屬的摩擦力帶動自由跟隨管子通過軋機,芯棒的運行速度是不受控的;軋制過程中芯棒的運行速度隨著各機架的咬入、拋鋼有波動,從而引起管子壁厚的波動;軋制結束后,芯棒隨荒管軋出至連軋機后的輸出輥道。在軋制中薄壁管時芯棒的全長幾乎都在荒管內,如圖4-3所示。帶有芯棒的荒管橫移至脫棒線,由脫棒機將芯棒從荒管中抽出以便冷卻、潤滑后循環使用。浮動芯棒連續軋管機的特點是軋制節奏快,每分鐘可軋4支甚至更多的不銹鋼管;但荒管的壁厚精度稍低,設有脫棒機其工藝流程較長,芯棒的長度接近于管子的長度;適合生產較小規格的無縫不銹鋼管。比較有代表性的浮動芯棒連續軋管機有德國米爾海姆廠的RK2機組和我國寶鋼的ф140mm機組。

連續(xu)軋(ya)(ya)(ya)(ya)(ya)(ya)管(guan)(guan)(guan)時,荒管(guan)(guan)(guan)可(ke)以看(kan)做(zuo)是(shi)在(zai)不同直(zhi)(zhi)徑(jing)的(de)(de)(de)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)間(jian)連續(xu)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)形成的(de)(de)(de),穿在(zai)不銹鋼管(guan)(guan)(guan)中(zhong)的(de)(de)(de)芯(xin)(xin)(xin)棒(bang)可(ke)以看(kan)做(zuo)是(shi)曲率(lv)半徑(jing)無(wu)窮(qiong)大(da)(da)的(de)(de)(de)內(nei)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)。浮(fu)動芯(xin)(xin)(xin)棒(bang)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)時,芯(xin)(xin)(xin)棒(bang)除受到(dao)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)經軋(ya)(ya)(ya)(ya)(ya)(ya)件(jian)傳遞來的(de)(de)(de)作用力外(wai),再無(wu)其(qi)(qi)他外(wai)力作用。當軋(ya)(ya)(ya)(ya)(ya)(ya)件(jian)頭部經第一(yi)(yi)機(ji)架(jia)(jia)(jia)(jia)(jia)(jia)咬入(ru)后(hou),隨(sui)著(zhu)軋(ya)(ya)(ya)(ya)(ya)(ya)件(jian)逐一(yi)(yi)走向后(hou)面(mian)(mian)的(de)(de)(de)延伸機(ji)架(jia)(jia)(jia)(jia)(jia)(jia),作用在(zai)芯(xin)(xin)(xin)棒(bang)上的(de)(de)(de)機(ji)架(jia)(jia)(jia)(jia)(jia)(jia)數相(xiang)繼增多(duo),故(gu)芯(xin)(xin)(xin)棒(bang)速度(du)(du)不斷提高,這個階段(duan)(duan)稱為(wei)(wei)“咬入(ru)”階段(duan)(duan);當軋(ya)(ya)(ya)(ya)(ya)(ya)件(jian)頭部進入(ru)最(zui)末機(ji)架(jia)(jia)(jia)(jia)(jia)(jia)后(hou),整個軋(ya)(ya)(ya)(ya)(ya)(ya)件(jian)處在(zai)連續(xu)軋(ya)(ya)(ya)(ya)(ya)(ya)管(guan)(guan)(guan)機(ji)所有(you)機(ji)架(jia)(jia)(jia)(jia)(jia)(jia)的(de)(de)(de)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)中(zhong),芯(xin)(xin)(xin)棒(bang)速度(du)(du)維持不變,稱為(wei)(wei)“穩(wen)(wen)定(ding)(ding)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)”階段(duan)(duan);當軋(ya)(ya)(ya)(ya)(ya)(ya)件(jian)尾部離開第一(yi)(yi)機(ji)架(jia)(jia)(jia)(jia)(jia)(jia)后(hou),芯(xin)(xin)(xin)棒(bang)速度(du)(du)逐級(ji)提高,直(zhi)(zhi)到(dao)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)結(jie)束,稱為(wei)(wei)“軋(ya)(ya)(ya)(ya)(ya)(ya)出”階段(duan)(duan)。軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)工作圓(yuan)周速度(du)(du)是(shi)按“穩(wen)(wen)定(ding)(ding)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)”狀態下設定(ding)(ding)的(de)(de)(de),軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)過程中(zhong)軋(ya)(ya)(ya)(ya)(ya)(ya)件(jian)又是(shi)遵循(xun)著(zhu)體積不變定(ding)(ding)律(lv)的(de)(de)(de)。然而由芯(xin)(xin)(xin)棒(bang)引起的(de)(de)(de)軋(ya)(ya)(ya)(ya)(ya)(ya)件(jian)速度(du)(du)的(de)(de)(de)升高,使(shi)流入(ru)后(hou)面(mian)(mian)機(ji)架(jia)(jia)(jia)(jia)(jia)(jia)的(de)(de)(de)金屬必然增多(duo),也就是(shi)說(shuo),后(hou)面(mian)(mian)的(de)(de)(de)機(ji)架(jia)(jia)(jia)(jia)(jia)(jia)由芯(xin)(xin)(xin)棒(bang)送人了比其(qi)(qi)設定(ding)(ding)的(de)(de)(de)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)圓(yuan)周速度(du)(du)所允許的(de)(de)(de)還要多(duo)的(de)(de)(de)金屬,這就出現(xian)了使(shi)斷面(mian)(mian)積增大(da)(da)的(de)(de)(de)金屬積累。這種逐步流入(ru)的(de)(de)(de)附加金屬造成的(de)(de)(de)較大(da)(da)斷面(mian)(mian),盡管(guan)(guan)(guan)在(zai)最(zui)后(hou)的(de)(de)(de)機(ji)架(jia)(jia)(jia)(jia)(jia)(jia)上得(de)到(dao)了加工,但仍然導致在(zai)荒管(guan)(guan)(guan)的(de)(de)(de)一(yi)(yi)些部位(wei)上直(zhi)(zhi)徑(jing)變大(da)(da)和壁(bi)厚(hou)變厚(hou),這種現(xian)象稱為(wei)(wei)“竹節”。原則上講可(ke)能(neng)在(zai)整根(gen)不銹鋼管(guan)(guan)(guan)上均出現(xian)“竹節”。顯然“竹節”現(xian)象屬縱向壁(bi)厚(hou)不均,對隨(sui)后(hou)的(de)(de)(de)張減機(ji)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)是(shi)不利(li)的(de)(de)(de),應(ying)盡可(ke)能(neng)防(fang)止。

為(wei)了防(fang)止(zhi)或減少“竹(zhu)節(jie)”形成(cheng),孔型設計分配壓下(xia)量時,在(zai)保證總延(yan)伸不變(bian)的(de)(de)前(qian)提下(xia),適(shi)當增(zeng)加(jia)前(qian)幾(ji)架(jia)壓下(xia)量。這樣,就可(ke)在(zai)后面幾(ji)個機(ji)架(jia)中(zhong)使(shi)芯(xin)(xin)棒(bang)速(su)度的(de)(de)躍增(zeng)得到減弱(ruo),從而(er)減輕芯(xin)(xin)棒(bang)速(su)度變(bian)化的(de)(de)影響。良(liang)好(hao)的(de)(de)芯(xin)(xin)棒(bang)潤滑(hua)有利于(yu)延(yan)伸和降(jiang)低能耗,也可(ke)以減少竹(zhu)節(jie)的(de)(de)形成(cheng)。還可(ke)以采用(yong)電控技術防(fang)止(zhi)竹(zhu)節(jie)的(de)(de)產生,由電子計算(suan)機(ji)進(jin)行預設定(ding),軋(ya)(ya)輥(gun)轉(zhuan)(zhuan)速(su)按要求(qiu)變(bian)化,當軋(ya)(ya)件(jian)通過時對軋(ya)(ya)輥(gun)轉(zhuan)(zhuan)速(su)進(jin)行校準(zhun),使(shi)各機(ji)架(jia)的(de)(de)出(chu)口速(su)度與(yu)芯(xin)(xin)棒(bang)速(su)度的(de)(de)變(bian)化相適(shi)應。

盡管(guan)對“竹節”現象采取了(le)(le)不少措施并取得了(le)(le)一定的(de)效果(guo),但軋(ya)(ya)制(zhi)條件(jian)的(de)變(bian)化依然存(cun)在,且(qie)成品管(guan)的(de)尺(chi)寸精(jing)度始終(zhong)不如限動芯(xin)棒(bang)軋(ya)(ya)機(ji)(ji)(ji)。此外,芯(xin)棒(bang)長(chang)(chang),使制(zhi)造費(fei)用(yong)加大,制(zhi)造困難,且(qie)長(chang)(chang)芯(xin)棒(bang)的(de)重量(liang)也很大,不銹鋼管(guan)帶著過重的(de)芯(xin)棒(bang)在輥(gun)道上(shang)運(yun)行將會導致不銹鋼管(guan)表面損傷。故目前(qian)浮動芯(xin)棒(bang)連續軋(ya)(ya)管(guan)機(ji)(ji)(ji)均用(yong)于小型機(ji)(ji)(ji)組(zu)(zu),至(zhi)今(jin)這種機(ji)(ji)(ji)組(zu)(zu)僅能生產直(zhi)徑小于177.8mm以(yi)下的(de)不銹鋼管(guan)。浮動芯(xin)棒(bang)連續軋(ya)(ya)管(guan)機(ji)(ji)(ji)機(ji)(ji)(ji)組(zu)(zu)在20世紀70年代之前(qian)比(bi)較盛行。