鎢極氬弧焊雖然能獲得優良的焊接質量,但由于受到鎢極許用電流的限制,焊接電流不能用得太大。一般鎢(wu)極氬弧焊進行對接接頭焊接時,板厚小于4mm可以焊透,超過此厚度的焊件不但需要開坡口,有時還需預熱才能施焊。所以鎢極氬弧焊焊接中、厚板時,生產效率低,勞動條件差,焊接變形大且影響焊接接頭耐蝕性,已不能滿足生產的需要。

熔化極氣體(ti)保護焊是用焊絲作為電極,焊接電流可以大大提高。由于熔深大,焊絲熔敷速度快,提高了勞動生產率。對于中、厚板焊接,焊前不需要預熱,改善了勞動條件,減少了焊接變形,同時還有利于提高焊接接頭耐蝕性。熔化極氣體保護焊適用于中等和大厚度板材的焊接,在生產中已得到廣泛使用。

熔(rong)(rong)化(hua)(hua)極氣體保(bao)護(hu)焊(han),是用可(ke)熔(rong)(rong)化(hua)(hua)的(de)焊(han)絲(si)(si)(si)與(yu)被焊(han)工件之間的(de)電(dian)弧作(zuo)(zuo)為熱(re)源來(lai)熔(rong)(rong)化(hua)(hua)焊(han)絲(si)(si)(si)和母材金屬(shu)(shu),并(bing)(bing)向焊(han)接區輸送保(bao)護(hu)氣體。保(bao)護(hu)氣體能(neng)使電(dian)弧、熔(rong)(rong)化(hua)(hua)的(de)焊(han)絲(si)(si)(si)、熔(rong)(rong)池(chi)(chi)及(ji)附近金屬(shu)(shu)免受周(zhou)圍(wei)空(kong)氣的(de)有害作(zuo)(zuo)用。通過(guo)連續送進焊(han)絲(si)(si)(si)不斷(duan)熔(rong)(rong)化(hua)(hua)并(bing)(bing)過(guo)渡到熔(rong)(rong)池(chi)(chi),最后形(xing)成(cheng)焊(han)縫金屬(shu)(shu)。

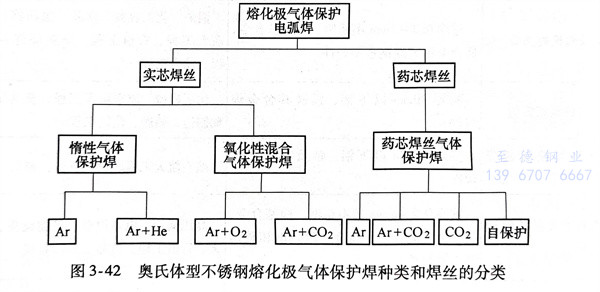

奧氏體(ti)不銹(xiu)鋼熔化極氣體保護焊的種類和不同焊絲形式分類見圖3-42。

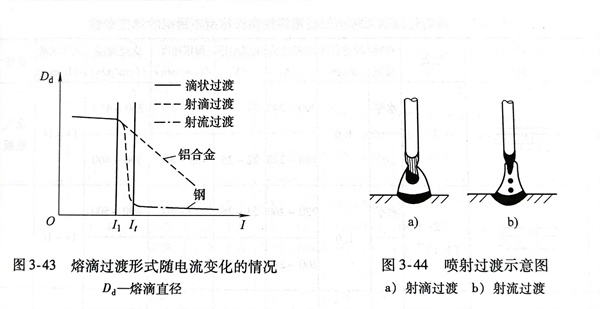

熔(rong)(rong)(rong)化極氣體保護焊(han)(han)焊(han)(han)接(jie)奧氏體型(xing)(xing)不(bu)銹(xiu)鋼時(shi)的熔(rong)(rong)(rong)滴(di)過(guo)(guo)渡(du)類(lei)型(xing)(xing)有滴(di)狀過(guo)(guo)渡(du)、短(duan)路過(guo)(guo)渡(du)和噴(pen)(pen)射過(guo)(guo)渡(du)三種。其中,滴(di)狀過(guo)(guo)渡(du)時(shi),熔(rong)(rong)(rong)滴(di)直(zhi)徑比焊(han)(han)絲直(zhi)徑大,飛(fei)濺(jian)較大,導致焊(han)(han)接(jie)過(guo)(guo)程不(bu)穩定,在(zai)生產(chan)上極少使用(yong);短(duan)路過(guo)(guo)渡(du)電(dian)(dian)(dian)弧間隙小,電(dian)(dian)(dian)弧電(dian)(dian)(dian)壓較低,電(dian)(dian)(dian)弧功(gong)率比較小,適(shi)用(yong)于薄板焊(han)(han)接(jie);生產(chan)中應用(yong)最(zui)為廣泛的是噴(pen)(pen)射過(guo)(guo)渡(du),對于一定直(zhi)徑焊(han)(han)絲和保護氣體,當焊(han)(han)接(jie)電(dian)(dian)(dian)流增大到臨界電(dian)(dian)(dian)流值時(shi)(見圖(tu)3-43)焊(han)(han)絲端頭熔(rong)(rong)(rong)化的金屬被壓縮成筆(bi)尖狀,以細小熔(rong)(rong)(rong)滴(di)從液柱尖端高速軸(zhou)向射入熔(rong)(rong)(rong)池,即(ji)噴(pen)(pen)射過(guo)(guo)渡(du),如圖(tu)3-44所示。

一、熔化極(ji)惰性氣體保(bao)護焊

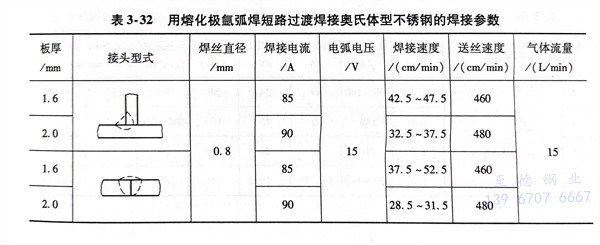

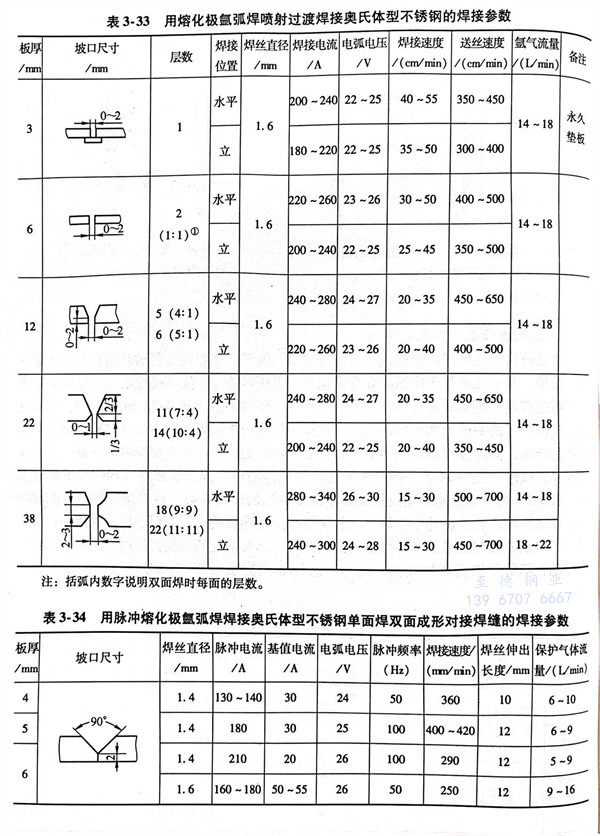

熔(rong)化(hua)(hua)極惰性(xing)氣體(ti)保(bao)護焊(han)(han)(han)(han)(han)(han)(han)(han)(han)的(de)(de)(de)(de)(de)惰性(xing)氣體(ti)通常采用(yong)(yong)氬(ya)(ya)氣。該焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)工藝已開始(shi)在(zai)許多領域(yu)中得到(dao)使用(yong)(yong),其中經機(ji)械操作縱縫焊(han)(han)(han)(han)(han)(han)(han)(han)(han)應(ying)用(yong)(yong)最多。焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)時選(xuan)擇直流(liu)反(fan)極性(xing)電(dian)源。以(yi)短(duan)路過(guo)渡和噴射過(guo)渡的(de)(de)(de)(de)(de)熔(rong)滴形式進(jin)行操作,其坡口尺寸和焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)參數見表3-32和表3-33。在(zai)熔(rong)化(hua)(hua)極氬(ya)(ya)氣保(bao)護焊(han)(han)(han)(han)(han)(han)(han)(han)(han)的(de)(de)(de)(de)(de)基礎上加入脈沖(chong)(chong)電(dian)流(liu)即成(cheng)脈沖(chong)(chong)熔(rong)化(hua)(hua)極氬(ya)(ya)弧焊(han)(han)(han)(han)(han)(han)(han)(han)(han),它(ta)不僅具(ju)有(you)熔(rong)化(hua)(hua)極氬(ya)(ya)弧焊(han)(han)(han)(han)(han)(han)(han)(han)(han)所有(you)的(de)(de)(de)(de)(de)特點,同(tong)(tong)時能控制焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)熱輸入,控制金屬熔(rong)池,使焊(han)(han)(han)(han)(han)(han)(han)(han)(han)縫正反(fan)面成(cheng)形良好,實現單(dan)面焊(han)(han)(han)(han)(han)(han)(han)(han)(han)雙(shuang)面成(cheng)形。表3-34為(wei)(wei)一組脈沖(chong)(chong)熔(rong)化(hua)(hua)極氬(ya)(ya)弧焊(han)(han)(han)(han)(han)(han)(han)(han)(han)的(de)(de)(de)(de)(de)單(dan)面焊(han)(han)(han)(han)(han)(han)(han)(han)(han)雙(shuang)面成(cheng)形對接(jie)(jie)(jie)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)縫的(de)(de)(de)(de)(de)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)參數。表3-35為(wei)(wei)一組脈沖(chong)(chong)熔(rong)化(hua)(hua)極氬(ya)(ya)弧焊(han)(han)(han)(han)(han)(han)(han)(han)(han)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)角焊(han)(han)(han)(han)(han)(han)(han)(han)(han)縫的(de)(de)(de)(de)(de)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)參數。在(zai)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)同(tong)(tong)樣厚度的(de)(de)(de)(de)(de)材料時,焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)熱輸入比非脈沖(chong)(chong)熔(rong)化(hua)(hua)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)小,相應(ying)地減(jian)少了熱影響區(qu),有(you)利于(yu)(yu)提(ti)高(gao)耐蝕(shi)性(xing);同(tong)(tong)時減(jian)少了焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)應(ying)力與變形。脈沖(chong)(chong)電(dian)流(liu)的(de)(de)(de)(de)(de)熱循環(huan)對金屬熔(rong)池能起到(dao)攪拌作用(yong)(yong),有(you)利于(yu)(yu)細(xi)化(hua)(hua)焊(han)(han)(han)(han)(han)(han)(han)(han)(han)縫結晶,降低(di)產(chan)生(sheng)裂(lie)紋的(de)(de)(de)(de)(de)傾(qing)向。此外(wai),這種焊(han)(han)(han)(han)(han)(han)(han)(han)(han)接(jie)(jie)(jie)方法可以(yi)減(jian)輕勞(lao)動強(qiang)度,提(ti)高(gao)生(sheng)產(chan)效率。

二(er)、熔化極混合氣體保護焊

采用混合氣體(ti)保護作為保護氣體(ti)具有下列(lie)優(you)點:

1. 可(ke)以提(ti)高熔滴過渡的穩定性;

2. 穩定陰極斑點(dian),提高(gao)電弧燃(ran)燒的穩定性;

3. 增大電弧的熱功率,改(gai)善焊縫熔深和外觀成(cheng)形,使焊縫能呈圓滑過渡,焊縫的余高適(shi)中(zhong)。

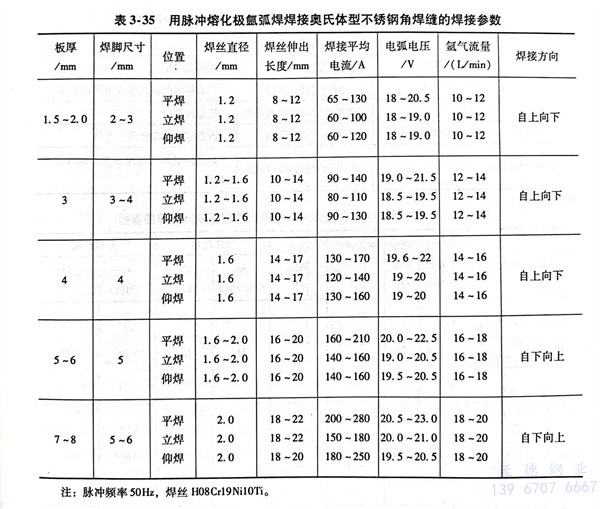

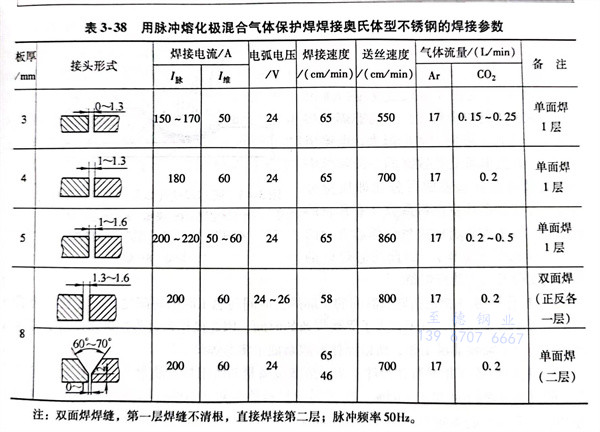

混合氣體是在氬氣的基礎上加體積分數為0.5%~1.0%的氧或加體積分數1%~5%的二氧化碳作為保護氣體。這時,焊接過程比較穩定,焊絲端部呈細熔滴過渡,焊縫成形有所改善。混合氣體的組成成分對焊絲的熔滴過渡形式和焊接特性的影響,見表3-36。在生產上應用比較廣泛的是在混合氣體保護下的脈沖焊接工藝。例如,Ar+O2混合氣體的脈沖焊,其焊接參數見表3-37;Ar+CO2混合氣體焊的焊接參數見表3-38。奧氏體型不銹鋼的熔化極氣體保護焊一般采用細焊絲,焊絲熔化速度很快,電弧熱量集中。為了保證焊縫外表和內在質量,用手工操作焊不太可能達到這一目的,廣泛應用的是機械操作的脈沖熔化極氣體保護焊。

焊接(jie)電(dian)源一般采用(yong)平(ping)特性(xing)(xing),為直(zhi)流正接(jie)連接(jie)。采用(yong)脈沖焊時,脈沖電(dian)源為平(ping)特性(xing)(xing),維(wei)弧電(dian)源用(yong)平(ping)特性(xing)(xing)或降特性(xing)(xing),仍為直(zhi)流正極(ji)性(xing)(xing)。

脈沖(chong)熔化極氣(qi)體保(bao)護焊(han)的焊(han)接(jie)設備比較(jiao)復雜,價格較(jiao)高。需要調整的焊(han)接(jie)參(can)數較(jiao)多,焊(han)工需要進行專門(men)培訓才能上崗操作(zuo)。

三(san)、藥(yao)芯焊(han)絲(si)電弧焊(han)

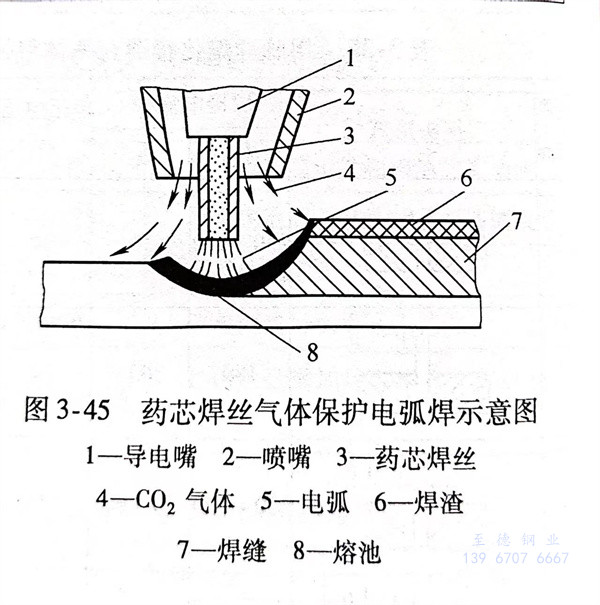

藥芯焊(han)(han)(han)絲(si)(si)按(an)結(jie)構分(fen)為有(you)(you)(you)(you)縫焊(han)(han)(han)絲(si)(si)(有(you)(you)(you)(you)多種截面形式)和(he)無縫焊(han)(han)(han)絲(si)(si)(可鍍銅)。藥芯焊(han)(han)(han)絲(si)(si)按(an)填料來又分(fen)有(you)(you)(you)(you)藥粉型(有(you)(you)(you)(you)造渣劑(ji))和(he)金(jin)(jin)屬(shu)粉劑(ji)型(無造渣劑(ji))。藥芯焊(han)(han)(han)絲(si)(si)電弧焊(han)(han)(han)是(shi)依靠(kao)藥芯焊(han)(han)(han)絲(si)(si)在(zai)高溫(wen)時(shi),反應形成(cheng)的(de)(de)(de)熔(rong)(rong)(rong)(rong)渣和(he)氣(qi)(qi)(qi)體(ti)(ti)聯合(he)自行(xing)保(bao)護(hu)(hu)(hu)焊(han)(han)(han)接區(qu)進(jin)(jin)行(xing)焊(han)(han)(han)接的(de)(de)(de)方法(fa),也有(you)(you)(you)(you)加外加保(bao)護(hu)(hu)(hu)氣(qi)(qi)(qi)體(ti)(ti)的(de)(de)(de)。它與普(pu)(pu)通(tong)熔(rong)(rong)(rong)(rong)化(hua)極氣(qi)(qi)(qi)體(ti)(ti)電弧焊(han)(han)(han)一樣,是(shi)以熔(rong)(rong)(rong)(rong)化(hua)的(de)(de)(de)藥芯焊(han)(han)(han)絲(si)(si)作(zuo)(zuo)為一個電極,母材(cai)金(jin)(jin)屬(shu)作(zuo)(zuo)為另一個電極,在(zai)兩極間(jian)燃燒電弧進(jin)(jin)行(xing)焊(han)(han)(han)接。焊(han)(han)(han)接奧(ao)氏(shi)體(ti)(ti)型不(bu)銹(xiu)鋼時(shi),通(tong)常(chang)外加保(bao)護(hu)(hu)(hu)氣(qi)(qi)(qi)體(ti)(ti)來保(bao)護(hu)(hu)(hu)藥芯焊(han)(han)(han)絲(si)(si)、熔(rong)(rong)(rong)(rong)池(chi)(chi)和(he)母材(cai)金(jin)(jin)屬(shu)。與普(pu)(pu)通(tong)熔(rong)(rong)(rong)(rong)化(hua)極氣(qi)(qi)(qi)體(ti)(ti)保(bao)護(hu)(hu)(hu)焊(han)(han)(han)的(de)(de)(de)主要區(qu)別(bie)在(zai)于不(bu)用實芯焊(han)(han)(han)絲(si)(si)而(er)用內部裝有(you)(you)(you)(you)焊(han)(han)(han)劑(ji)混合(he)物的(de)(de)(de)藥芯焊(han)(han)(han)絲(si)(si)。焊(han)(han)(han)接時(shi),在(zai)保(bao)護(hu)(hu)(hu)氣(qi)(qi)(qi)體(ti)(ti)氣(qi)(qi)(qi)氛(fen)中,在(zai)電弧熱的(de)(de)(de)作(zuo)(zuo)用下(xia),熔(rong)(rong)(rong)(rong)化(hua)狀(zhuang)態的(de)(de)(de)焊(han)(han)(han)劑(ji)材(cai)料、焊(han)(han)(han)絲(si)(si)金(jin)(jin)屬(shu)、母材(cai)金(jin)(jin)屬(shu)相互之(zhi)間(jian)發生(sheng)冶金(jin)(jin)作(zuo)(zuo)用,同時(shi)形成(cheng)一層較薄的(de)(de)(de)液態熔(rong)(rong)(rong)(rong)渣包覆熔(rong)(rong)(rong)(rong)滴(di)并覆蓋熔(rong)(rong)(rong)(rong)池(chi)(chi),對熔(rong)(rong)(rong)(rong)池(chi)(chi)金(jin)(jin)屬(shu)形成(cheng)又一層保(bao)護(hu)(hu)(hu)。實質上這種焊(han)(han)(han)接方法(fa)是(shi)一種氣(qi)(qi)(qi)渣聯合(he)保(bao)護(hu)(hu)(hu)的(de)(de)(de)方法(fa),如圖(tu)3-45所示(shi)。

不銹鋼藥芯焊絲氣體保護焊焊接方法分藥芯焊絲電弧焊(FCAW)和氣體保護焊。氣體保護形式:有自保護、CO2氣體保護和混合氣體保護(75~85%Ar+CO2),施焊時采用直流反接電流;惰性氣體電弧焊(GTAW)氣體保護為100%Ar,施焊時采用直流正接電流。

藥芯(xin)焊(han)絲氣體保護焊(han)綜合了焊(han)條(tiao)電弧(hu)焊(han)和熔化極(ji)氣體保護焊(han)的優點。其特點如下:

1. 熔敷(fu)速度快

(熔(rong)敷速(su)度(du)(du)是指單(dan)位(wei)時間熔(rong)敷到焊(han)(han)(han)縫(feng)中(zhong)金屬量(liang))藥(yao)芯焊(han)(han)(han)絲與(yu)藥(yao)皮(pi)焊(han)(han)(han)條(tiao)相比(bi),可使用的電流(liu)大,電流(liu)密度(du)(du)更大,而且其填充(chong)系(xi)(xi)數(shu)(同一段焊(han)(han)(han)絲中(zhong)藥(yao)粉重(zhong)量(liang)與(yu)金屬重(zhong)量(liang)的百(bai)分(fen)比(bi)即(ji)質(zhi)量(liang)分(fen)數(shu)%)小(xiao)于(yu)焊(han)(han)(han)條(tiao)藥(yao)皮(pi)涂料系(xi)(xi)數(shu)(有藥(yao)皮(pi)的同一段焊(han)(han)(han)條(tiao)上焊(han)(han)(han)條(tiao)藥(yao)皮(pi)重(zhong)量(liang)與(yu)焊(han)(han)(han)芯重(zhong)量(liang)的百(bai)分(fen)比(bi)即(ji)質(zhi)量(liang)分(fen)數(shu)%),因此藥(yao)芯焊(han)(han)(han)絲的熔(rong)敷速(su)度(du)(du)明顯大于(yu)藥(yao)皮(pi)焊(han)(han)(han)條(tiao)。

2. 操作系數(shu)

(指包括燃弧(hu)時(shi)(shi)間(jian)(jian)的(de)實際焊(han)接時(shi)(shi)間(jian)(jian)與總工時(shi)(shi)的(de)時(shi)(shi)間(jian)(jian)之(zhi)比(bi))比(bi)較,藥芯焊(han)絲(si)與藥皮焊(han)條相比(bi),由(you)于(yu)省去了更換焊(han)條的(de)時(shi)(shi)間(jian)(jian),因此操作系數明顯提(ti)高;與實芯焊(han)絲(si)相比(bi),由(you)于(yu)需要(yao)清渣工作,所以操作系數略低于(yu)實芯焊(han)絲(si)。

3. 材料(liao)系數

(指材料(liao)在焊(han)(han)件上實際熔敷金屬(shu)量(liang)與所(suo)用材料(liao)質量(liang)之比)比較,藥芯焊(han)(han)絲(si)的材料(liao)效(xiao)(xiao)率(lv)約為78%~85%,實芯焊(han)(han)絲(si)材料(liao)效(xiao)(xiao)率(lv)高達(da)90%,埋弧(hu)焊(han)(han)的材料(liao)效(xiao)(xiao)率(lv)約為40%~55%,藥皮焊(han)(han)條大約65%~70%。

4. 減少填充(chong)金屬比較(jiao)

由于(yu)藥芯焊(han)(han)絲熔深較大,而且焊(han)(han)絲易于(yu)深入坡(po)(po)口(kou)底部,所以允許(xu)采用較大的坡(po)(po)口(kou)鈍(dun)邊和較小(xiao)的坡(po)(po)口(kou)角度,減少了填充到焊(han)(han)縫金屬(shu)的數量。

藥芯(xin)焊(han)絲與實(shi)(shi)芯(xin)焊(han)絲相比,其(qi)優越之處主要表(biao)現在芯(xin)部焊(han)藥的(de)作用,由于藥芯(xin)焊(han)絲的(de)芯(xin)部加有穩(wen)弧劑、造渣(zha)劑和(he)合金(jin)(jin)劑,從(cong)而使電弧燃燒穩(wen)定,熔(rong)滴過(guo)渡平穩(wen),克服了實(shi)(shi)芯(xin)焊(han)絲在施焊(han)過(guo)程中的(de)飛濺大、表(biao)面成形差等缺陷;并能提高全位置焊(han)接,有適應性。另外,由于藥芯(xin)焊(han)絲可通過(guo)金(jin)(jin)屬管坯(pi)和(he)藥芯(xin)兩(liang)種途徑過(guo)渡合金(jin)(jin)元素,有助(zhu)于合金(jin)(jin)元素的(de)調整,使焊(han)縫金(jin)(jin)屬力學性能特(te)別是沖(chong)擊(ji)性能得到提高,并且(qie)也使焊(han)縫金(jin)(jin)屬耐蝕性得到提高。

藥芯焊絲氣體保護焊焊接奧氏體型不銹鋼時,可采用機械化焊接,但通常使用廣泛的仍是手工操作焊接方法。焊接設備選用普通的CO2氣體保護設備即可。氣體可選擇用CO2氣體;也可用CO2+Ar混合氣體,但氬氣比例超過80%時,反而會使焊縫中形成氣孔。

藥(yao)芯(xin)(xin)焊(han)絲(si)(si)斷(duan)面(mian)結(jie)構有不(bu)(bu)同形(xing)(xing)式,如圖(tu)2-1所(suo)示。“O”形(xing)(xing)斷(duan)面(mian)藥(yao)芯(xin)(xin)焊(han)絲(si)(si)由(you)于焊(han)絲(si)(si)內部的焊(han)劑不(bu)(bu)導(dao)(dao)電(dian),電(dian)弧易沿鋼皮(pi)旋(xuan)轉:當直(zhi)徑較(jiao)(jiao)大(da)時,電(dian)弧穩定性(xing)較(jiao)(jiao)差,飛濺增大(da),焊(han)縫成(cheng)分可能(neng)出現(xian)不(bu)(bu)夠均(jun)(jun)勻的現(xian)象。其直(zhi)徑2.4mm的藥(yao)芯(xin)(xin)焊(han)絲(si)(si)在生產上(shang)得到(dao)應(ying)用。折疊式焊(han)絲(si)(si)因管坯在整個斷(duan)面(mian)上(shang)分布比較(jiao)(jiao)均(jun)(jun)勻,藥(yao)芯(xin)(xin)焊(han)絲(si)(si)內部亦能(neng)導(dao)(dao)電(dian),所(suo)以電(dian)弧燃燒穩定,焊(han)絲(si)(si)熔化均(jun)(jun)勻,冶(ye)金(jin)反(fan)應(ying)充分,容易獲得優(you)質的焊(han)縫。直(zhi)徑大(da)于2.4mm時,更顯出這些優(you)勢。

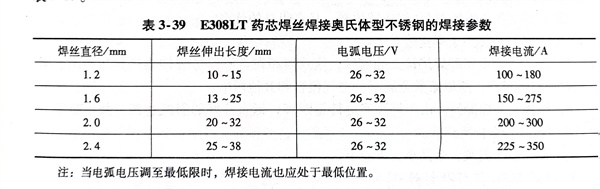

藥芯焊絲氣體保護焊的焊接參數主要有焊接電流、電弧電壓、焊接速度、焊絲伸出長度和保護氣體流量等。當其他條件不變時,焊接電流與送絲速度成正比;焊接電流變化時,電弧電壓要相應的變化;采用純CO2氣體保護焊時,通常采用長弧法焊接,焊接電流調節范圍廣,可達200~700A,電弧電壓為25~35V。焊絲伸出長度太長會使電弧不穩定,飛濺過大;焊絲伸出長度過短,會造成過多的飛濺物堵塞噴嘴,使氣體保護不好,焊縫中易產生氣孔。通常焊絲伸出長度在19~38mm范圍內。平焊位置時焊槍前進方向與焊件之間的傾角為2°~15°;焊接角焊縫時為40°~50°。如果角度太大,會降低氣體保護效果。下面介紹一組用E308LT藥芯焊絲焊接奧氏體型不銹鋼的焊接參數,見表3-39。